**stress Concentration Factor Influences**

In today’s engineering landscape, understanding the ins and outs of stress concentration factor influences is not just beneficial, but essential for anyone involved in design and material optimization. Imagine a world where structures and components can be designed with enhanced durability and efficiency—this is the power of leveraging stress concentration factor influences. Your ability to optimize these influences can significantly reduce structural failures, increase safety, and optimize costs. Let’s explore how this critical aspect can transform engineering feats from good to outstanding.

Read Now : Obd-ii Diagnostic Trouble Code Meanings

The Importance of Stress Concentration Factor Influences

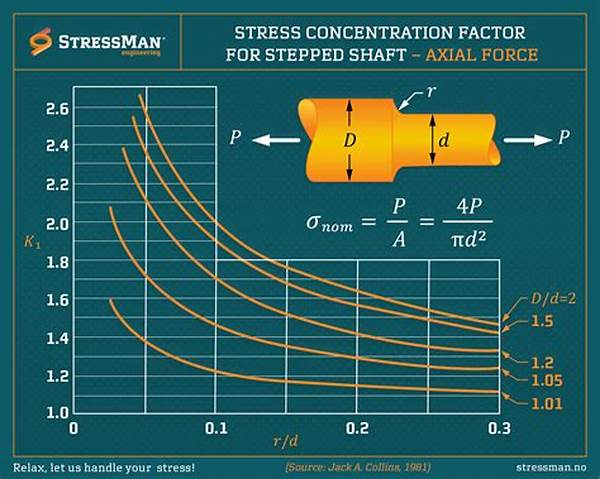

Understanding stress concentration factor influences is crucial because they dictate how materials and structures respond under load. They’re a vital consideration in ensuring the longevity and safety of a design. Stress concentration factors, caused by discontinuities and changes in a material’s geometry, can lead to stress points that are significantly higher than the nominal stress. This phenomenon can result in unexpected failures, often at stress levels lower than anticipated during the design phase.

By mastering stress concentration factor influences, engineers can predict and mitigate these high-stress regions. This knowledge contributes to the development of safer and more reliable structures. Furthermore, addressing stress concentrations early in the design process can lead to innovations in material use, potentially reducing costs. Failure to adequately manage these influences could not only increase the risk of part failure but also lead to costly redesigns. As technology advances, the necessity of understanding stress concentration factor influences is paramount for maintaining competitiveness in the engineering field.

5 Key Explanations of Stress Concentration Factor Influences

1. Stress concentration factor influences can magnify local stresses in a material, making it crucial to identify and address them to prevent unexpected failures.

2. By understanding stress concentration factor influences, engineers can design components that are lighter, more efficient, and more cost-effective, without compromising safety.

3. In advanced engineering applications, mastering stress concentration factor influences is key to developing innovative products and maintaining a technological edge.

4. Accurate prediction and modeling of stress concentration factor influences help extend the lifespan of components, reducing maintenance costs and downtime.

5. Addressing stress concentration factor influences in the early design stage can drastically improve product reliability and consumer trust.

Harnessing Stress Concentration Factor Influences

Tackling stress concentration factor influences head-on is an opportunity to push the boundaries of engineering design. When engineers focus on minimizing these influences early in the design phase, the benefits extend beyond immediate performance improvements. Addressing stress concentration factor influences not only contributes to the durability of a product but also opens doors to material cost savings that can be reinvested into other critical areas of development.

The advancement of computational tools and simulation software has revolutionized how we handle stress concentration factor influences. Engineers can now visualize potential problem areas quickly, making it easier to iterate on designs and find optimal solutions. This efficiency translates into faster time-to-market for new products and the ability to meet increasing demands for high-performance solutions. Emphasizing stress concentration factor influences is not just about preventing failure—it’s about leveraging cutting-edge capabilities to redefine what’s possible in engineering.

Strategic Approaches to Stress Concentration Factor Influences

To effectively manage stress concentration factor influences, engineers employ various strategic approaches that harness the power of technology and innovation. By utilizing advanced simulation tools, engineers can model stress concentration factor influences with unprecedented accuracy, enabling precise predictions and preemptive design adjustments. This proactive stance significantly reduces the likelihood of structural failures, instilling confidence in the finalized design.

Read Now : Comprehensive Car Service Guarantees

Material innovation also plays a critical role in managing stress concentration factor influences. By employing composites and advanced alloys that distribute stress more evenly, engineers minimize critical stress points. Additionally, adopting iterative testing and validation processes ensures that the engineered solutions meet performance expectations under various conditions. By prioritizing stress concentration factor influences, companies not only innovate but also establish themselves as industry leaders in safety and reliability.

Unveiling the Impact of Stress Concentration Factor Influences

Stress concentration factor influences are complex phenomena that cannot be overlooked. They serve as a roadmap for engineers striving to enhance both the performance and resilience of their designs. When neglected, stress concentration factor influences can lead to catastrophic failures, but when harnessed, they reveal opportunities for breakthrough engineering solutions.

By delving into stress concentration factor influences, engineers uncover hidden insights about material behavior and structural resilience. This understanding translates directly to improved safety standards, as designs can be optimized to withstand unanticipated stressors. Moreover, acknowledging stress concentration factor influences fosters innovation by challenging conventional methodologies and encouraging novel approaches. Together, these advantages underscore why stress concentration factor influences should be an integral consideration in every engineering project.

Exploring the Role of Stress Concentration Factor Influences

The exploration of stress concentration factor influences unveils intriguing opportunities for technological advancement and improved product performance. By grasping their role, designers and engineers can refine their approaches, transforming potential weaknesses into strengths. This proactive handling of stress concentration factor influences sets a new standard in the industry, where failure isn’t just prevented but anticipated and defied.

When companies integrate stress concentration factor influences into their core strategies, the focus shifts from merely avoiding issues to creating robust, long-lasting products. This proactive thinking opens avenues for developing cutting-edge designs that push the envelope of what’s possible. Additionally, it instills a culture of continuous improvement, reinforcing commitment to quality and excellence. Stress concentration factor influences serve not just as challenges but as catalysts for innovation and superior performance.

Conclusion: Embracing Stress Concentration Factor Influences

In conclusion, stress concentration factor influences are a keystone in the realm of engineering design. Mastering these influences is a gateway to developing safer, more efficient, and forward-thinking solutions. By integrating stress concentration factor influences into regular engineering scrutiny and design methodologies, companies position themselves as pioneers in a competitive market space, emphasizing quality and resilience at all levels.

The importance of stress concentration factor influences cannot be overstated. They embody a hidden potential within every material and design, awaiting the keen eye of the engineer to unlock. As the technological landscape evolves, so does the necessity for understanding and leveraging these critical influences. Organizations embracing this knowledge stand to gain not only in market share but also in consumer trust and industry respect.