Scheduling Preventive Maintenance Tasks

In today’s competitive business landscape, ensuring the seamless operation of your machinery and equipment is more important than ever. Companies that fail to implement effective preventive maintenance schedules often find themselves caught off guard by sudden breakdowns and costly downtimes. Scheduling preventive maintenance tasks not only prevents these disruptions but also enhances the efficiency and longevity of your assets. It’s time to embrace proactive stewardship of your equipment and see the profound impact it can have on your bottom line. Imagine the power of consistent, well-timed checks that keep your operations running smoothly, minimize unexpected failures, and optimize productivity. Investing in a strategic approach to maintenance is not just about safeguarding machinery; it’s about securing the future of your business and maintaining a competitive edge. Don’t wait for problems to arise; act now by scheduling preventive maintenance tasks and watch as your business operations transcend to new heights of reliability and efficiency.

Read Now : Locked-out Vehicle Recovery Support

The Importance of Scheduling Preventive Maintenance

Scheduling preventive maintenance tasks is crucial for any business that relies on machinery or equipment. These tasks ensure that potential issues are identified and resolved before they become significant problems, saving time and money. Proactively managing maintenance schedules reduces downtime and enhances operational efficiency, leading to an overall increase in productivity. By scheduling preventive maintenance tasks, businesses can extend the lifespan of their equipment, prevent unexpected breakdowns, and create a safer work environment for employees. This proactive approach not only ensures the optimal performance of assets but also instills confidence in stakeholders, demonstrating a commitment to excellence and long-term success. Making the decision to prioritize preventive maintenance is a strategic move that reflects foresight, responsibility, and dedication to realizing the best possible outcomes for your business operations.

Key Benefits of Scheduling Preventive Maintenance

1. Improved Equipment Longevity: Scheduling preventive maintenance tasks ensures regular check-ups that can significantly extend the life of machinery, reducing the need for expensive replacements.

2. Reduced Downtime: By addressing issues before they result in breakdowns, scheduling preventive maintenance tasks minimizes downtime, keeping operations running smoothly.

3. Cost Savings: Preventive measures are generally less expensive than reactive fixes or replacements, leading to substantial cost savings over time.

4. Enhanced Safety: Regular maintenance checks reduce the risk of equipment failure that could lead to accidents, ensuring a safer environment for employees.

5. Boosted Efficiency: Well-maintained equipment operates more efficiently, increasing productivity and allowing businesses to meet their operational goals more effectively.

Read Now : **hydroelectric Power Generation Components**

Strategies for Effective Scheduling Preventive Maintenance

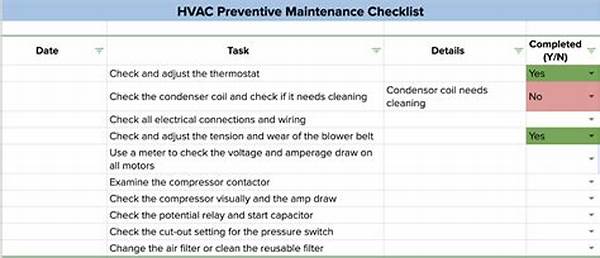

To maximize the benefits of scheduling preventive maintenance tasks, businesses should develop a comprehensive plan that includes detailed inspections, parts replacement schedules, and routine service tasks. It’s essential to tailor the maintenance schedule to the specific needs of your equipment, taking into consideration factors such as usage frequency, environmental conditions, and manufacturer recommendations. Utilizing advanced management software can streamline the scheduling process, providing real-time updates and ensuring that maintenance is carried out efficiently and consistently. By investing time and resources into creating meticulous preventive maintenance schedules, companies demonstrate a commitment to quality and reliability, ultimately fostering a culture of proactive care and continuous improvement. Remember, the success of preventive maintenance hinges on consistency, foresight, and an unwavering dedication to the highest standards of operational excellence.

Scheduling Preventive Maintenance: A Continuous Improvement Journey

The journey of scheduling preventive maintenance tasks is an ongoing process that demands constant evaluation and adjustment. It’s about creating a culture of vigilance and foresight, where maintenance is not an afterthought but a core component of operational strategy. Integrating IoT and predictive analytics can bring unprecedented insights into your maintenance processes, enabling a deeper understanding of equipment performance and facilitating more informed decisions. Embrace this opportunity to leverage cutting-edge technology in maintenance planning and witness the transformation it brings to your business operations. As your business evolves, so too should your maintenance strategies, adapting to emerging challenges and capturing new efficiencies. The true mark of a successful preventive maintenance program is its ability to evolve in response to changing needs, keeping your assets in peak condition and your business at the forefront of industry standards.

How to Implement an Effective Preventive Maintenance Program

Implementing an effective preventive maintenance program involves a strategic blend of planning, execution, and evaluation. Begin with a thorough assessment of your equipment’s current condition and performance history, identifying areas of vulnerability that require immediate attention. Develop a detailed schedule of maintenance tasks, prioritizing high-impact inspections and replacements while remaining flexible to accommodate unexpected needs. Engage your team in the process, ensuring that they have the training and resources necessary to execute maintenance tasks efficiently and safely. Utilize modern software solutions for tracking task completion, monitoring equipment status, and maintaining an organized record of past activities. By emphasizing clarity, consistency, and accountability, your preventive maintenance program can transform from a simple task list into a robust framework for operational excellence, driving long-term success and instilling confidence in your capability to manage your assets effectively.

The Role of Leadership in Preventive Maintenance Success

Leadership plays a pivotal role in the success of scheduling preventive maintenance tasks. It is the responsibility of management to champion this initiative, integrating it seamlessly into the broader framework of company objectives and culture. Communicate the strategic importance of preventive maintenance to all levels of the organization, ensuring alignment with business goals and fostering a shared commitment to asset care. Encourage cross-departmental collaboration, leveraging unique insights and expertise to enhance maintenance processes. By cultivating an environment where preventive maintenance is prioritized and valued, managers set the tone for operational diligence and proactive equipment management. Leadership isn’t just about setting policies; it’s about inspiring action and fostering the shared responsibility necessary for sustainable success. Through decisive action and ongoing support, leaders can elevate scheduling preventive maintenance tasks from mere protocol to a cornerstone of organizational resilience and success.