Fatigue Failure In Mechanical Systems

Mechanical systems are the backbone of modern industry, yet many of them are at constant risk of fatigue failure—an insidious occurrence that leads to unexpected and often catastrophic failures. Imagine the seamless operation of a factory brought to an abrupt stop, or the integrity of an aerospace component compromised. These aren’t just hypothetical scenarios; they highlight the critical nature of understanding, monitoring, and addressing fatigue failure in mechanical systems. This article delves into the complexities of this phenomenon, revealing why it should not merely be an afterthought but a strategic priority for engineers and businesses alike.

Read Now : Streamlined Vehicle Operation Management

Understanding Fatigue Failure

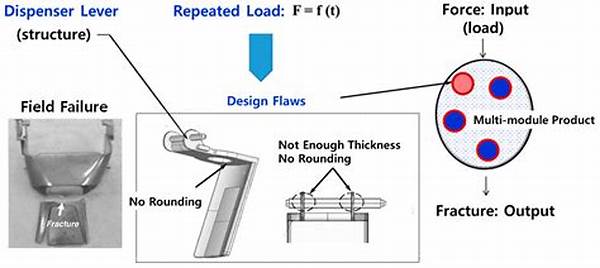

Fatigue failure in mechanical systems is a process that occurs in three distinct stages: crack initiation, crack propagation, and finally, catastrophic failure. At its core, it is the result of cyclic stresses that are often well below the material’s ultimate tensile strength, making it deceptively elusive. Consider a bridge constantly under the stress of traffic or a turbine blade enduring repetitive rotations—over time, these repetitions cause minute cracks to develop and widen. Addressing fatigue failure requires an intricate understanding of the materials, their stress limits, and environmental factors. Neglecting these elements can lead to disastrous failures with severe economic repercussions and potential safety hazards.

The engineering community has devoted significant resources to understanding fatigue failure in mechanical systems, yet this phenomenon demands continuous attention and innovation. As technology advances, systems become more complex, and the fatigue life predictions must evolve accordingly. While the initial investments in fatigue analysis might seem substantial, the long-term benefits of prolonging equipment lifespan and ensuring safety far outweigh the costs. In a world where safety and efficiency are paramount, the proactive management of fatigue failure is not just desirable—it is essential.

The Consequences of Ignoring Fatigue Failure

1. Operational Downtime: Ignoring fatigue failure in mechanical systems can lead to unexpected breakdowns, resulting in costly operational downtimes and production losses.

2. Increased Maintenance Costs: Regular failures demand frequent repairs, spiking maintenance budgets and diverting resources from innovation and growth.

3. Safety Hazards: Overlooking fatigue failure poses significant safety risks, potentially leading to accidents that can cause injuries or fatalities.

4. Reputation Damage: Companies that experience frequent mechanical failures may suffer reputational damage, affecting their competitiveness and market position.

5. Legal Liabilities: Failing to address fatigue failure can lead to legal actions, particularly if negligence is proven in cases of accidents or equipment failures.

Advancements in Monitoring Techniques

Innovations in fatigue failure detection are crucial in today’s high-tech environments. Advanced monitoring techniques, such as non-destructive testing and real-time fatigue monitoring systems, are being developed and deployed to combat fatigue failure in mechanical systems. Such technologies allow for early detection of potential failures, giving engineers the upper hand in preventing catastrophic breakdowns.

Embracing these innovations not only ensures the smooth operation of mechanical systems but also protects investments and lives. A proactive approach to fatigue failure combines the latest technology with strategic maintenance planning, elevating standard safety protocols to new heights. Organizations that invest in these tools and methodologies can vastly improve reliability and safety, fostering an environment where innovation is both safeguarded and propelled.

Strategies for Prevention

1. Regular Inspections: Routine inspections are crucial to identify early signs of fatigue failure in mechanical systems and prevent further deterioration.

2. Material Selection: Using robust materials designed to withstand cyclic stresses is essential in preventing fatigue-related issues.

3. Design Modifications: Implementing design changes that reduce stress concentrations can significantly mitigate fatigue failure risks.

4. Advanced Simulations: Utilizing advanced simulation tools allows engineers to predict potential fatigue failure in mechanical systems and make informed decisions.

Read Now : Affordable Vehicle Maintenance Strategies

5. Employee Training: Educating employees about fatigue failure and preventive maintenance ensures they are vigilant and proactive in identifying potential issues.

6. Up-to-date Technology: Employing cutting-edge technology for monitoring and maintenance can reduce the likelihood of fatigue failure in mechanical systems.

7. Environmental Controls: Controlling environmental conditions, such as temperature and humidity, minimizes their impact on system fatigue.

8. Load Management: Effective management of load and stress distribution across systems can extend equipment life and prevent fatigue failure.

9. Routine Maintenance: Regular maintenance schedules ensure systems are functioning optimally and identify weaknesses before they result in failures.

10. Stakeholder Collaboration: Collaboration between engineers, manufacturers, and stakeholders enhances the understanding and management of fatigue failure in mechanical systems.

Case Study: A Lesson from Industry

Consider the case of an airline company whose routine aircraft maintenance program overlooked micro-cracking in one of its fleet’s wings. This oversight led to a significant fatigue failure in mechanical systems, grounding the aircraft and incurring substantial financial losses. By investing in state-of-the-art monitoring technologies, the company has since revamped its maintenance checks, preventing future occurrences and enhancing overall safety.

This case study underscores the importance of vigilance and technology in managing fatigue failure. The airline, once beleaguered by an oversight, now stands as an example of how proactive measures can transform risk into resilience. Their journey serves as a compelling argument for organizations worldwide to prioritize fatigue failure management, turning potential weaknesses into strengths.

The Future of Stress Testing

The trajectory of fatigue failure in mechanical systems is being reshaped by advances in stress testing technologies. Future innovations promise deeper insights and more precise anticipations of system failures. As the industry moves forward, the adoption of sophisticated modeling and predictive analytics will revolutionize how fatigue is managed.

Harnessing these technologies will lead to unprecedented efficiencies, transforming fatigue failure from a looming threat into a manageable challenge. For companies to remain competitive and responsible, embracing these changes is non-negotiable. As fatigue management evolves, so too does the ability to safeguard investments and lives, highlighting the profound impact of strategic foresight in engineering.

Conclusion

In conclusion, the imperative to address fatigue in mechanical systems transcends mere technical requirements; it is integral to business success and safety. Fatigue failure exists as a persistent threat, demanding attention through rigorous analysis and state-of-the-art monitoring. Organizations that seize the opportunity to innovate fatigue management will not only prevent failures but will position themselves as leaders in safety and reliability. The time to act is now, ensuring that mechanical systems are not just operational, but optimized for the future.