Failure Mode And Effects Analysis

In the ever-evolving world of business, the key to outpacing competitors often lies not just in innovation but in preempting potential pitfalls before they occur. Imagine having a crystal ball that allows you to anticipate and mitigate risks. This is not a dream but a reality with Failure Mode and Effects Analysis (FMEA). By adopting FMEA, organizations can transform uncertainties into manageable scenarios, enhancing their capability to deliver high-quality products and services consistently. It’s a proactive approach that every forward-thinking organization should incorporate into its strategy.

Read Now : Reliable Brake Maintenance Professionals

Understanding the Essence of FMEA

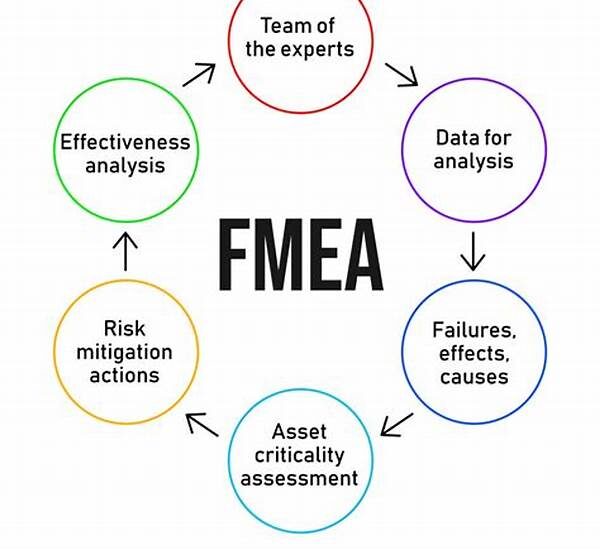

Failure Mode and Effects Analysis is a systematic approach to identify where and how a system might fail. These “failure modes” are potential errors or defects within a process, product, or design. FMEA assesses the impact of different types of failure, thereby prioritizing the actions needed to mitigate them. By investing in Failure Mode and Effects Analysis, businesses can enhance their problem-solving techniques, hence reducing costs associated with failures and improving customer satisfaction. This analysis is not merely a tool but an investment in quality, enabling organizations to foresee potential risks and address them proactively. Therefore, embracing FMEA is not just a recommendation but a necessity for companies aiming for excellence.

Implementing FMEA: A Strategic Necessity

1. Proactive Risk Management: With failure mode and effects analysis, organizations can predict potential failures and address them before they affect operations.

2. Cost Efficiency: By preventing errors before they occur, FMEA reduces unnecessary costs associated with process failures and product defects.

3. Improved Product Quality: Implementing failure mode and effects analysis ensures high-quality products by identifying and mitigating risks during the development phase.

4. Enhanced Customer Satisfaction: Satisfied customers result from products that meet expectations, made possible through meticulous failure mode and effects analysis.

5. Strategic Decision Making: FMEA provides insights and data, empowering leaders to make informed and strategic decisions.

The Critical Role of FMEA in Product Development

In product development, employing Failure Mode and Effects Analysis is akin to possessing a powerful shield against unforeseen issues. By systematically evaluating every possible point of failure, businesses can ensure that they deliver reliable and robust products to their customers. This proactive measure not only saves time and resources but also cultivates a reputation for reliability and innovation.

The adoption of Failure Mode and Effects Analysis facilitates a culture of continuous improvement and vigilance. It instills a mindset that every potential error must be addressed and corrected, optimizing the value delivered to customers. When companies recognize the power of FMEA in fortifying their operations against risks, they naturally become champions of quality and innovation, securing their place at the forefront of their industries.

Benefiting from FMEA Across Industries

1. Automotive Industry: Failure mode and effects analysis ensures vehicle safety and compliance with industry standards.

2. Healthcare Sector: FMEA mitigates risks associated with medical procedures, enhancing patient safety and care quality.

3. Manufacturing Process: By identifying potential failures, FMEA improves operational efficiency and reduces downtime.

4. Aerospace Applications: Failure mode and effects analysis is critical in ensuring aircraft reliability and passenger safety.

Read Now : Extensive Car Maintenance Plans

5. Software Development: Employing FMEA helps prevent bugs and enhances software performance by identifying and addressing potential risks.

6. Consumer Electronics: FMEA aids in delivering defect-free products, enhancing brand reputation and consumer trust.

7. Construction Projects: Failure mode and effects analysis identifies potential project risks, ensuring timely and successful project completion.

8. Pharmaceutical Industry: Mitigating risks through FMEA ensures product efficacy and compliance with health regulations.

9. Energy Sector: FMEA enhances plant operations by preventing power outages and equipment malfunctions.

10. Food and Beverage Industry: By ensuring quality control, FMEA maintains product safety and regulatory compliance.

Why FMEA is Indispensable

Failure Mode and Effects Analysis is not merely a methodology but a critical factor in achieving operational excellence. Its importance cannot be overstated; with FMEA, businesses secure a competitive advantage by consistently delivering superior quality. It is through this process that potential failures are transformed into opportunities for improvement, making it a cornerstone of successful organizations.

Embracing Failure Mode and Effects Analysis can change the trajectory of a company’s growth. By identifying and addressing potential risks early in development, businesses can avoid costly mistakes and build trust with their clientele. FMEA is more than risk management; it is a commitment to quality and a testament to visionary thinking—a non-negotiable part of any progressive organization’s strategy.

Persuasive Power of FMEA in Business Strategy

Failure mode and effects analysis stands as a testament to strategic foresight. It empowers businesses to tackle potential issues head-on, ensuring that operations run smoothly and efficiently. By incorporating FMEA into the core framework of business operations, companies not only mitigate risks but also enhance their credibility and reliability in the eyes of stakeholders.

More than just a risk assessment tool, Failure Mode and Effects Analysis fosters a philosophical shift towards unwavering quality and continuous improvement. It challenges organizations to anticipate risks and convert them into avenues for innovation and growth. This transformative approach not only sets companies apart from the competition but solidifies their status as leaders in their respective markets. Every forward-thinking enterprise should prioritize FMEA as a core component of their strategy for sustained growth and success.