Engine Performance Monitoring Systems

Understanding Engine Performance Monitoring Systems

In today’s fast-paced world, staying ahead of the competition means optimizing every aspect of your operations, and the engine is no exception. Investing in robust engine performance monitoring systems can transform the way you manage your machinery and vehicles. These systems provide real-time data that is crucial for maintaining operational efficiency and prolonging the life of your engines. Imagine reducing downtime, minimizing repair costs, and maximizing productivity simply by having a deeper insight into engine performance. Embrace the future of technology and consider upgrading your monitoring systems today for unparalleled results tomorrow.

Read Now : Neighborhood Transmission Repair Specialists

Engine performance monitoring systems are not just an optional add-on; they are an essential tool for any industry reliant on engines. They compile a vast range of metrics, alerting you to potential issues before they become costly problems. With these advanced systems, you are equipped to make informed decisions based on accurate, real-time data. This proactive approach can significantly reduce the risk of unexpected breakdowns, ensuring you maintain a competitive edge in your field.

To overlook engine performance monitoring systems is to invite inefficiency and uncertainty into your operations. By leveraging the power of these systems, you invest in the longevity and reliability of your assets. In a world where time and efficiency translate directly to profitability, can you afford not to implement the best in monitoring technology? Take control of your engines and your future with engine performance monitoring systems.

Key Benefits of Engine Performance Monitoring Systems

1. Reduce Downtime: Engine performance monitoring systems provide real-time alerts, enabling prompt action to prevent engine failures and reduce costly downtime.

2. Increase Efficiency: By analyzing performance data, these systems help optimize engine operations, ensuring peak efficiency and fuel savings.

3. Extend Engine Life: Regular monitoring allows for timely maintenance and repairs, significantly extending the lifespan of your engines.

4. Operational Savings: By minimizing repairs and optimizing performance, engine performance monitoring systems contribute to operational cost savings.

5. Competitive Advantage: Businesses utilizing these systems can operate with greater reliability, providing a distinct edge over competitors not using such technology.

Enhancing Operations with Engine Performance Monitoring Systems

Incorporating engine performance monitoring systems into your operational strategy isn’t just about keeping pace with technological advancements; it’s about setting new standards in efficiency and reliability. These systems provide a wealth of actionable insights that empower you to optimize every aspect of engine functionality and performance. As engines are crucial to numerous industries, having a system that can continuously monitor and report their status in real-time offers unmatched peace of mind.

Consider the long-term benefits to your organization when you integrate engine performance monitoring systems. These systems not only identify and troubleshoot issues but also offer predictive insights that can prevent future problems. This foresight not only extends the life of your equipment but also maximizes the return on your investment. The importance of such a strategic approach cannot be overstated, and those who embrace it will likely lead the pack in the competitive arena.

The Impact of Engine Performance Monitoring Systems

1. Insightful Analytics: Engine performance monitoring systems offer analytics that uncover irregular patterns, which can be crucial for preventive measures.

2. Comprehensive Data: Real-time data streams allow for constant vigilance, ensuring no hidden issues go unnoticed.

3. Improved Safety: By predicting potential failures, these systems enhance operational safety, protecting both assets and personnel.

4. Environmental Benefits: Optimizing engine performance reduces emissions, contributing environmentally friendly operations.

5. Tailored Solutions: Many systems offer customizable features to meet specific operational needs, enhancing user experience and effectiveness.

Read Now : Fleet Service History Database

6. User-Friendly Interface: Designed for ease of use, these systems don’t require extensive training, making them accessible for all levels of staff.

7. Cost-Efficiency: By preventing costly repairs and downtime, engine performance monitoring systems are a cost-effective investment.

8. Scalability: These systems can easily scale to accommodate growing operational needs, offering a future-proof solution.

9. Strategic Asset Management: The detailed information provided helps in strategic planning and asset management.

10. Peace of Mind: Knowing that your engines are operating at optimum levels brings immeasurable peace of mind.

Exploring the Dimensions of Engine Performance Monitoring Systems

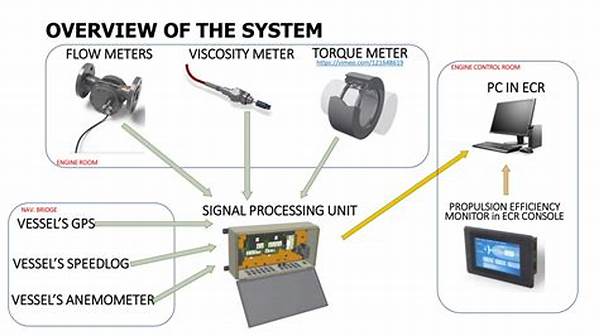

When implementing engine performance monitoring systems, it’s crucial to understand the multifaceted benefits that they bring to the table. These systems collect data on critical engine parameters such as temperature, pressure, and fuel consumption. The analysis of this data empowers businesses to respond swiftly to emerging issues, effectively minimizing the risk of unplanned outages and costly repairs.

Moreover, engine performance monitoring systems facilitate enhanced resource allocation and maintenance planning. With insights driven by real-time data, companies can align their operational strategies with the actual needs of their equipment, avoiding excessive maintenance and reducing operational expenditure. Such precision and agility in operations not only lead to significant cost savings but also empower decision-makers to cultivate a resilient and adaptable business model.

The Evolution of Engine Performance Monitoring Systems

Engine performance monitoring systems have evolved dramatically over the years, transforming from simple diagnostic tools to sophisticated platforms built on big data and analytics. These advancements are indispensable for industries operating in challenging environments where engine reliability is paramount. With cutting-edge technologies, these systems provide a competitive advantage, helping businesses stay ahead of potential operational pitfalls and maintain a steady path toward growth.

By leveraging such advanced tools, organizations can shift from reactive to proactive maintenance strategies. This shift is critical for enhancing the reliability and efficiency of fleets, resulting in improved customer satisfaction, compliance with regulatory standards, and an overall boost in return on investment. Embracing engine performance monitoring systems today ensures a reliable and prosperous tomorrow by safeguarding the integrity of operational assets and processes.

A Strategic Approach to Engine Performance Monitoring Systems

The necessity of engine performance monitoring systems for modern industry cannot be overemphasized. As engines serve as the backbone of many operations, ensuring their optimal performance is imperative. With a detailed understanding of engine conditions facilitated by these systems, businesses are equipped to make informed decisions swiftly and accurately. The strategic implementation of these systems can help mitigate risks associated with unexpected engine failures and enhance overall operational efficacy.

Moreover, the integration of engine performance monitoring systems promotes a culture of continuous improvement. By consistently analyzing engine data, organizations can identify patterns and trends, making informed adjustments to refine and improve operational practices. The proactive stance adopted with these systems ensures that companies can navigate the challenges of their industry with greater efficiency and agility, securing a robust and sustainable future.