Engine Fault Identification Methods

In a world driven by machinery and technology, the efficiency of engines plays an undeniable role in the smooth operation of numerous sectors. Identifying engine faults swiftly and accurately can save time and money, while preventing disastrous downtime and potential safety hazards. Now, more than ever, businesses and individuals need to understand engine fault identification methods to safeguard their investments and ensure an uninterrupted workflow. By engaging in a proactive approach to engine maintenance, you can protect not only the longevity of your machinery but also the safety of your operations.

Read Now : Professional Automotive Brake Testing Services

Innovative Techniques for Engine Fault Identification

Engine fault identification methods have evolved tremendously, blending traditional mechanical insights with cutting-edge technology. Modern techniques range from visual inspections to sophisticated diagnostics tools that pinpoint anomalies with pinpoint accuracy. Investing in state-of-the-art engine fault identification methods ensures you stay steps ahead of potential breakdowns. Imagine the peace of mind knowing every inch of your engine is monitored, every rumble analyzed, and every hiccup diagnosed before it can evolve into a costly issue. Prioritizing these advanced diagnostic tools can save substantial costs, prevent downtime, and optimize your machine’s performance. The assurance they offer makes them an indispensable part of any maintenance strategy.

Embracing modern engine fault identification methods means leveraging technology to detect issues early on. These methods significantly reduce the risk of severe engine damage, thereby extending the engine’s lifespan. They utilize advanced algorithms and sensors to continuously monitor engine performance, offering real-time feedback and alerts when parameters deviate from the norm. This early detection not only saves money on repairs but also minimizes the risk of unscheduled downtimes, ensuring the continuity and reliability of operations. Furthermore, by implementing these state-of-the-art methods, you uphold standards of safety and efficiency, translating into a more streamlined and reliable operational environment.

Benefits of Using Engine Fault Identification Methods

1. Proactive Maintenance: Utilizing engine fault identification methods allows for proactive maintenance, minimizing the risk of sudden breakdowns and costly repairs.

2. Cost Savings: Early identification of faults means less extensive repairs, saving money in the long run.

3. Enhanced Safety: By identifying potential issues early, engine fault identification methods contribute to a safer working environment, reducing accident risks.

4. Increased Efficiency: Keeping engines in optimal condition enhances their performance and reliability, ensuring efficient operations.

5. Environmental Impact: Properly functioning engines are more eco-friendly. Engine fault identification methods help in maintaining engines at their best, reducing harmful emissions.

The Future of Engine Fault Identification Methods

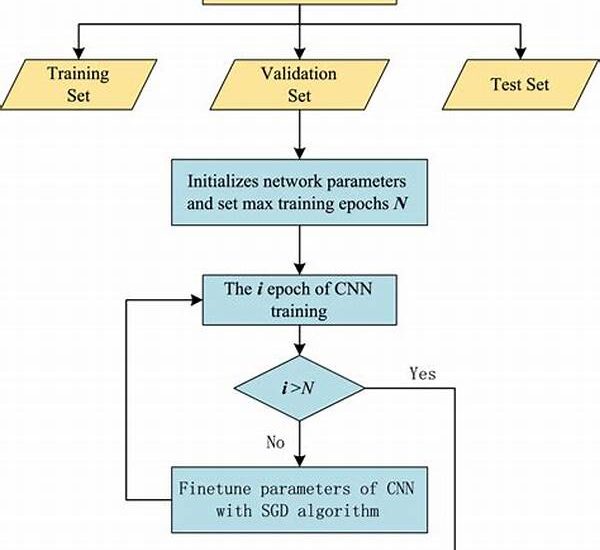

Technology continues to advance at an unprecedented rate, introducing more efficient and reliable engine fault identification methods. Artificial intelligence and machine learning are shaping the future, enabling predictive maintenance capabilities that were once unimaginable. Imagine systems that not only identify faults instantly but also predict potential future issues based on patterns and data. These advancements in engine fault identification methods promise a future where engine failures are nearly obsolete, replaced by knowledgeable predictions and robust solutions.

Moreover, the integration of IoT with engine fault identification methods is revolutionizing the field. Real-time data transmission to centralized systems allows for instantaneous fault alerts and remote diagnostics, facilitating quicker response times and precision in addressing engine concerns. These solutions are not just a luxury but an essential progression for industries that depend heavily on machinery health for their operations. By adopting these forward-thinking engine fault identification methods, businesses not only safeguard their assets but also ensure sustainability in their operational practices.

Read Now : Hybrid Vehicle Brake Component Replacement

Revolutionizing Maintenance with Engine Fault Identification Methods

Engine fault identification methods are revolutionizing the way maintenance is conducted. Gone are the days when maintenance was purely reactive, costing companies valuable time and resources. Now, through advanced diagnostics, engine faults can be detected, analyzed, and resolved before they manifest into severe problems. The ability to foresee and address faults proactively empowers businesses to maintain high levels of productivity and efficiency.

Moreover, integrating these modern engine fault identification methods within standard maintenance practices means transitions to more sustainable and effective strategies. The emphasis shifts from routine and sometimes unnecessary checks to targeted actions based on real-time data and predictions. This not only optimizes resource use but also enhances the overall reliability of machinery. As a result, operational downtime is minimized, and engine lifespan is maximized, offering significant financial and operational benefits.

Importance of Adopting Engine Fault Identification Methods

In our increasingly mechanized world, overlooking the efficiency and health of engines can lead to disastrous outcomes. The adoption of engine fault identification methods is imperative for anyone relying on machinery. Early fault detection translates into fewer breakdowns, reduced repair costs, and extended machinery lifespans. By adopting these vital methods, you ensure that your operations run smoothly and efficiently, without the looming dread of unexpected mechanical failures.

Furthermore, understanding the importance of engine fault identification methods extends beyond immediate business benefits. In the fast-paced world of industrial technology, it is a strategic move toward future-proofing operations. The advanced data analysis and predictive capabilities these methods provide allow companies to adapt and thrive in changing conditions, ensuring long-term success. Embracing these methods is not just about reacting to issues but proactively enhancing the machinery’s and organization’s overall intelligence and robustness.

Summary of Engine Fault Identification Methods

Engine fault identification methods are crucial in enhancing the performance and reliability of machinery. Their proactive approach to maintenance and early detection abilities ensures that engines are maintained in optimal condition, limiting downtime and reducing repair costs. This advantage becomes a competitive edge for businesses, as efficient engine management directly correlates with productivity and long-term success. Implementing these identification methods transforms potential challenges into opportunities for improvement and innovation.

Moreover, in adapting to these advanced engine fault identification methods, organizations can transition into smarter operational processes. This shift towards more intelligent maintenance systems reflects a broader trend towards integrating technology and data-driven solutions into business strategies. The insights gained from these methods provide organizations with the ability to make informed maintenance decisions, ensuring sustainable operations and fostering a culture of continuous improvement. This alignment not only enhances immediate operational capacities but paves the way for future growth and innovation.