**endurance Limit Testing Techniques**

Understanding the Importance of Endurance Limit Testing Techniques

Are you ready to push the boundaries of material durability to new heights? The secret lies in the mastery of endurance limit testing techniques. Today’s industries demand more than just strong materials—they demand materials that endure. Traditional methods no longer suffice in an era of advanced engineering and cutting-edge design. Investing in state-of-the-art endurance limit testing techniques is your gateway to achieving unparalleled product longevity. Imagine increasing the reliability and lifespan of products, leading to higher customer satisfaction and reduced costs. By adopting modern endurance limit testing techniques, you not only stay ahead of the competition but also ensure safety and efficiency in every product delivered.

Read Now : Synthetic Oils For Better Cooling

Understanding and implementing endurance limit testing techniques means more than just technical proficiency; it signifies a commitment to excellence and quality. Professionals who emphasize these techniques demonstrate an awareness of how critical these assessments are in predicting a material’s performance over an extended period. When the spotlight is on delivering uncompromising quality amid the competitive pressures of the market, employing superior endurance limit testing techniques becomes indispensable. Stand out as a leader in your field by prioritizing these tests and showcasing your dedication to perfection.

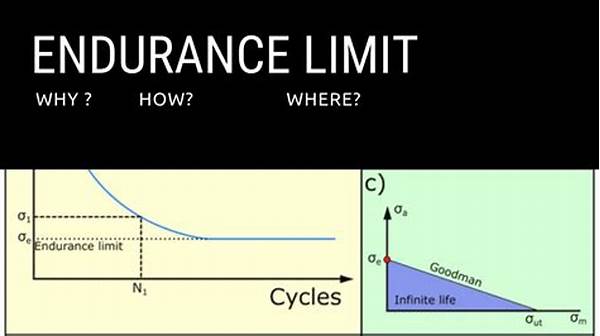

Moreover, if reliability is your benchmark, then endurance limit testing techniques are your map. As these methodologies evolve, they not only forecast the endurance of materials under fluctuating stresses but also empower researchers and engineers with insights into possible improvements and innovations. Adopting and constantly updating your approach to these techniques is not just a strategic advantage; it’s an industry necessity. Dive into endurance limit testing techniques and unlock the realm of possibilities in product enhancement.

Five Compelling Reasons to Adopt Endurance Limit Testing Techniques

1. Ensure Product Durability: By applying endurance limit testing techniques, manufacturers can guarantee that their products meet high durability standards, assuring customers of long-term value.

2. Enhance Safety Measures: Industries prioritizing safety see immediate benefits from endurance limit testing techniques, as these methods identify potential failure points before they become critical.

3. Reduce Long-term Costs: Investing in endurance limit testing techniques today defers costly repairs and replacements tomorrow through early identification of vulnerabilities.

4. Innovate with Confidence: These techniques allow companies to innovate fearlessly, knowing they have robust testing to back the durability and reliability of new materials.

5. Satisfy Regulatory Standards: Stay compliant with industry regulations and guidelines through rigorous and comprehensive endurance limit testing techniques.

The Growing Necessity of Endurance Limit Testing Techniques in Modern Industry

In today’s rapidly advancing technological landscape, the application of endurance limit testing techniques has become a pivotal component of product development strategies. Industries ranging from automotive to aerospace and even consumer electronics are reaping the benefits of employing these sophisticated methodologies. Consumers are demanding more reliable, longer-lasting products, and companies are responding by committing to endurance limit testing techniques to meet these expectations.

As the industry competition intensifies, standing out requires more than just innovative designs; it necessitates proving that a product can withstand the test of time. Incorporating endurance limit testing techniques showcases a brand’s commitment to quality and reliability, setting it apart as a leader in the market. Being at the forefront of implementing these testing techniques also reflects a proactive approach to continuous improvement and a dedication to customer satisfaction. This commitment not only enhances brand reputation but also fosters loyalty among consumers who seek products that deliver consistent performance over time.

Detailed Insights on Endurance Limit Testing Techniques

1. Comprehensive Analysis: Endurance limit testing techniques offer a thorough understanding of material behaviors under stress, which is vital for predicting their long-term performance.

2. Accurate Forecasting: Through precise measurements, these techniques provide accurate predictions about a material’s lifespan, helping in better product lifecycle management.

3. Informed Decision-Making: Detailed insights obtained from endurance limit testing techniques enable businesses to make strategic decisions regarding material selection and product design.

4. Improved Product Development: The knowledge gained from these techniques informs engineers while creating designs that enhance product reliability and efficiency.

5. Enhanced Competitive Edge: Businesses that leverage endurance limit testing techniques gain a significant advantage over competitors through the delivery of superior products.

Read Now : Electric Drivetrain Repair Training Certification

6. Innovation Catalyst: These techniques serve as a catalyst for innovation by highlighting areas for potential improvement in materials and processes.

7. Extended Product Warranty: Companies confidently offer extended warranties knowing their products can endure due to robust testing methodologies.

8. Sustainability Boost: Implementing these techniques promotes sustainability by ensuring that products are durable, reducing waste over time.

9. Risk Mitigation: Proper application of endurance limit testing techniques reduces the risk of product failure, safeguarding both brand reputation and customer trust.

10. Tailored Solutions: These techniques allow for the customization of testing procedures to meet specific industry needs, ensuring more relevant and applicable results.

Why Endurance Limit Testing Techniques are Essential for Industry Success

Endurance limit testing techniques are not just a fleeting trend; they are the backbone of robust product development and a staple in industries striving for excellence. Utilizing these techniques allows you to expand the capabilities of your products while reassuring your clients of their steadfast performance and safety. Imagine introducing a product that not only meets industry benchmarks but exceeds customer expectations with its unparalleled endurance—an achievement made possible through diligent testing.

The necessity for endurance limit testing techniques becomes even more pronounced when one considers the ever-rising competition and consumer awareness in today’s marketplace. Products are scrutinized not just for their immediate functionality but for their longevity and dependability in the face of prolonged exposure to stress. Companies that embrace these techniques illustrate a level of professionalism and foresight that directly contributes to lasting success and credibility.

Furthermore, as industries evolve, so too must their methodologies. Endurance limit testing techniques continue to evolve, offering more refined insights that drive innovation and efficiency. By remaining committed to these techniques, you enable a culture of quality and precision, inspiring confidence among consumers and stakeholders alike. It’s time to harness the full potential of endurance limit testing techniques and become a beacon of excellence in your field.

The Strategic Value of Endurance Limit Testing Techniques in Production

In an era where consumer expectations are continuously advancing, the strategic implementation of endurance limit testing techniques becomes vital. These techniques serve as the cornerstone for creating premium products that not only satisfy customer needs but also define industry standards. By embedding these methodologies in the product development process, companies ensure reliability and foster consumer trust.

Endurance limit testing techniques empower businesses to deliver on their promises of quality and sustainability. Encountering fewer product failures translates to higher consumer confidence and loyalty. This approach is beneficial not only from a financial standpoint but also in establishing a business’s reputation as a leader in innovation and dependability.

Summary: Harnessing the Power of Endurance Limit Testing Techniques

Endurance limit testing techniques have revolutionized the way industries approach product durability. Incorporation of these methods means more than just ticking a box on a quality checklist—it signifies a strategic shift towards producing more resilient and trustworthy products. The critical insights gained from such testing are invaluable in predicting performance and setting new benchmarks for excellence.

In today’s highly competitive market, standing out requires more than innovation; it requires demonstrating that products can withstand real-world challenges. By embracing endurance limit testing techniques, companies reaffirm their dedication to delivering not just products, but solutions that endure. This commitment not only enhances customer satisfaction but also propels businesses towards lasting success.