Endurance Limit Determination Processes

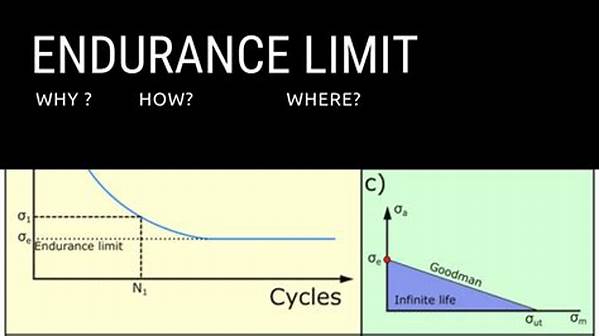

In a world where precision and reliability are paramount, understanding the endurance limit of materials is not just a technical necessity; it is an imperative for success. Imagine constructing a skyscraper or crafting a high-speed train. Without accurate endurance limit determination processes, these structures could fail, risking lives and investments. The endurance limit of a material signifies its ability to withstand repeated cycles of stress without experiencing failure. Harnessing the knowledge of endurance limits ensures designs that push boundaries, prioritize safety, and extend the lifespan of infrastructures and components. It’s time to embrace these processes as essential steps towards innovation and resilience in engineering and manufacturing.

Read Now : Home Car Waxing Techniques

The Importance of Endurance Limit Determination Processes

Endurance limit determination processes are the backbone of safe and efficient engineering designs. These processes unveil a material’s ability to endure stress and its subsequent resilience over time under repeated loadings. Understanding these processes isn’t merely about crunching numbers; it’s about foreseeing and preventing potential failures. Accurate endurance limit determination processes enable engineers to devise structures that offer not just utility but also unparalleled safety. Imagine reducing maintenance costs and improving sustainability simply by understanding how a material behaves under stress. By embedding these processes within the fabric of your design and manufacturing strategies, you join the forefront of technological advancement. Your investments in endurance limit determination processes are investments in the future—where innovations are seamlessly married with safety and efficiency.

Steps in Endurance Limit Determination Processes

1. Sample Preparation: The first step in endurance limit determination processes involves carefully preparing samples for testing. Precision is crucial here, as flaws in samples can lead to inaccurate results.

2. Loading and Cycling: This phase subjects the samples to controlled loadings to simulate real-world conditions—crucial for accurate endurance limit determination processes, ensuring your design reliability.

3. Monitoring and Data Collection: Advanced monitoring tools are employed to gather data during endurance limit determination processes. This data is invaluable for crafting more durable designs.

4. Analysis and Interpretation: Understanding the gathered data involves sophisticated analysis. Effective analysis galvanizes the endurance limit determination processes, leading to groundbreaking insights.

5. Application to Design: Implementing results into the design process fortifies the structures against fatigue, ensuring your engineering marvels pass the test of time.

Why Endurance Limit Determination is Crucial for Your Project

Endurance limit determination processes hold the key to the longevity and safety of your projects. As you embark on endeavors requiring impeccable durability, ignoring these processes could thwart your goals and compromise integrity. By prioritizing endurance limit determination processes, you leverage technology’s full potential, ensuring your designs are not only robust but also revolutionary. You redefine industry standards, offering more than just functionality—an assurance of safety. By incorporating these processes, you not only mitigate risks but also significantly reduce unforeseen costs. In the realm of hyper-competitive engineering, it’s the meticulous attention to endurance limit determination that sets your projects apart and builds trust with clients and stakeholders.

Deconstructing Endurance Limit Determination Steps

1. Identifying Material Relevance: Selecting materials for endurance limit determination processes is pivotal, as poor choices might compromise the entire venture.

2. Precision in Experimentation: The accuracy of endurance limit determination processes hinges on conducting meticulous experiments devoid of errors.

3. Utilizing Advanced Technologies: The efficiency of these processes is amplified by leveraging state-of-the-art technology that facilitates precision.

4. Interdisciplinary Integration: Implementing insights gleaned from these processes across disciplines ensures holistic improvements and innovations.

Read Now : Precision Diagnostics In Ev Maintenance

5. Continuous Learning and Adaptation: Embracing this mindset allows for the refinement of endurance limit determination processes, fostering sustainable progress.

6. Economizing Resources: By investing in precise endurance limit determination processes, you conserve financial and material resources, proving cost-effective in the long term.

7. Competitive Edge: Those who master these processes position their companies at the forefront, setting industry trends and grabbing significant market share.

8. Regulatory Compliance: Proper adherence ensures your projects meet stringent industry regulations, safeguarding against legal repercussions.

9. Client Satisfaction and Trust: Delivering projects that surpass client expectations on durability fosters client loyalty and trust.

10. Future-Proofing Designs: Incorporating accurate endurance limit determination processes prepares your designs to withstand future challenges and evolutions in technology.

Understanding Enhanced Durability Through Endurance Limit Processes

Every great design stands on the pillars of resilience and reliability. Endurance limit determination processes dissect the qualitative thresholds materials impose when challenged by repetitive stressors. Visualize a bridge enduring the unyielding forces of nature. Without precise endurance limit knowledge, a structure’s lifetime is unpredictable, which could lead to tragic consequences. This process acts as a technician’s map, plotting the course where innovation meets longevity. The meticulous process involves observing cycles, stress impacts, and translating them into data. This data then morphs into fortified designs where safety isn’t a feature but a fundamental essence. Investing in these processes ensures your projects not only survive but thrive through decades of wear and pressure, underscoring engineering excellence.

The Power of Analytical Precision in Engineering

Obsessed with accuracy, engineering driven by endurance limit determination processes can redefine possibilities. Imagine propelling your construction endeavors with unparalleled longevity, appealing not just to the current parameters of durability but surpassing them to achieve a legacy of safety and efficiency. Integrating these processes into your project from the onset not only prevents mishaps but also enhances resource utilization, saving time and costs. Your commitment to enduring strength is a testament to forward-thinking and strategic foresight. Each project isn’t just a standalone structure but a testament to mastery, ensuring safety in every principal by advocating endurance limit precision in every step of the design journey.