Cross-functional Maintenance Optimization Techniques

In today’s fast-paced and competitive business environment, the efficiency of your maintenance operations can make or break your bottom line. Imagine if there were a way to streamline these processes, reduce downtime, and significantly cut costs—all while enhancing productivity and creating a safer workplace. Enter cross-functional maintenance optimization techniques, a revolutionary approach designed to break down silos and promote synergy across departments. This comprehensive strategy is tailored to meet the unique demands of modern industries that are increasingly interconnected. By integrating these techniques, you unlock the potential for significant improvements in performance and reliability. The benefits are not only tangible but also transformative.

Read Now : Trends In Vehicle Repair Analysis

The Importance of Cross-Functional Maintenance Optimization Techniques

Cross-functional maintenance optimization techniques are pivotal in the transformation of maintenance operations from isolated tasks into cohesive efforts that elevate overall productivity. These techniques bring together various departments such as engineering, operations, and management to work collaboratively. The harmonization of expertise from different functions ensures that maintenance practices are both efficient and effective. For example, engineers can provide insights into technical challenges, while management offers strategic oversight, allowing for more informed decision-making. This integrated approach not only addresses immediate maintenance needs but also fosters a culture of continuous improvement and innovation. Ultimately, by adopting cross-functional maintenance optimization techniques, organizations are better equipped to adapt to changes, reduce costs, and maintain a competitive edge in their respective industries.

Key Components of Cross-Functional Maintenance Optimization Techniques

1. Collaboration Across Departments: By integrating diverse skill sets, cross-functional maintenance optimization techniques facilitate collaboration, ensuring that every aspect of maintenance receives the attention it deserves.

2. Enhanced Communication: These techniques emphasize clear and open communication channels among all stakeholders, reducing misunderstandings and fostering a unified approach to maintenance challenges.

3. Data-Driven Decision Making: By utilizing analytics and real-time data, cross-functional maintenance optimization techniques ensure that decisions are backed by concrete evidence, leading to more effective outcomes.

4. Resource Sharing: Pooling resources and knowledge across departments maximizes efficiency and reduces redundancy, making maintenance operations more streamlined and cost-effective.

5. Continuous Improvement: Cross-functional maintenance optimization techniques promote a culture of constant evaluation and enhancement, ensuring that maintenance practices evolve alongside technological advancements and industry trends.

Implementing Cross-Functional Maintenance Optimization Techniques

One of the most compelling reasons to adopt cross-functional maintenance optimization techniques is the holistic view they provide. By breaking down barriers and facilitating collaboration across departments, businesses can not only enhance efficiency but also improve their adaptability to industry changes. Imagine a scenario where engineering input aligns perfectly with operational requirements and management strategies—this is made possible through cross-functional maintenance optimization techniques. Streamlining processes in this manner reduces the likelihood of errors, minimizes downtime, and leads to significant cost reductions. Additionally, as departments work together towards common goals, employee satisfaction and morale improve, leading to a positive work environment conducive to innovation and growth.

This methodology doesn’t just offer short-term fixes; it creates lasting change by fostering a culture of open communication and shared objectives. Implementing cross-functional maintenance optimization techniques is a strategic investment that pays for itself by transforming your maintenance strategies into a well-oiled machine capable of facing future challenges efficiently and effectively.

Read Now : Cheap Automotive Repair Shops In Vicinity

Persuasive Benefits of Cross-Functional Maintenance Optimization Techniques

Impact of Cross-Functional Maintenance Optimization Techniques

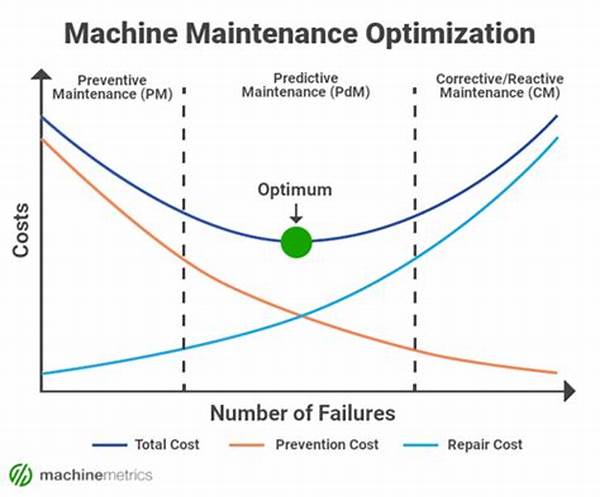

The adoption of cross-functional maintenance optimization techniques is a paradigm shift that offers long-lasting impact and advantages. Organizations leveraging these techniques report not only operational improvements but also strategic enhancements. With a united approach, departments can predict and prevent failures, thus minimizing downtime and saving costs. For instance, proactive maintenance facilitated by cross-functional maintenance optimization techniques means that companies can anticipate machinery failures and address them before they become costly breakdowns. This preemptive approach translates directly into enhanced operational efficiency and a more reliable production process. teamwork and shared responsibility foster employee engagement and lead to higher job satisfaction.

Moreover, as departments come together, knowledge transfer occurs more naturally, creating a learning organization that adapts swiftly to new technologies and processes. This continuous learning environment transforms challenges into opportunities for innovation, setting companies apart in the competitive landscape.

Roadmap to Implementing Cross-Functional Maintenance Optimization Techniques

The path to implementing cross-functional maintenance optimization techniques begins with an evaluation of current maintenance practices and the identification of areas for improvement. It demands a commitment to breaking down traditional silos and fostering a collaborative culture. Training programs can be instituted to build cross-functional teams equipped with the skills necessary for integrated maintenance strategies. These teams utilize shared goals and key performance indicators (KPIs) to track progress and ensure alignment in objectives.

Creating a systematic approach to communication ensures that information flows effortlessly across departments, which is essential for timely decision-making and strategic adjustments. Regular reviews of maintenance processes allow teams to identify successes and areas for further enhancement, iterating upon these techniques to suit the unique needs of the business. Adopting cross-functional maintenance optimization techniques is not a one-time initiative but a dynamic journey towards excellence and sustainability.

Transformative Power of Cross-Functional Maintenance Optimization Techniques

The summary effect of implementing cross-functional maintenance optimization techniques is indeed transformative. Organizations embracing this approach experience profound improvements in operational efficiency and strategic coherence. These techniques unite departments, driving unparalleled synergy that delivers tangible results. By merging insights from various functions, these optimization techniques facilitate informed decision-making processes that capitalize on collective intelligence.

As a result, maintenance becomes a strategic asset rather than just an operational necessity. Companies that leverage cross-functional maintenance optimization techniques find themselves better positioned to embrace change, drive innovation, and maintain growth momentum. This holistic approach not only optimizes resources but also elevates the entire organization’s capability to deliver value both internally and externally. The implementation resonates far beyond the maintenance department, fostering a culture of collaboration and continuous advancement across the entire organization.