Real-time Maintenance Alerts System

In today’s fast-paced industrial environment, efficiency and reliability are not just desired, they are essential. How many times have unexpected machine failures halted your operations, burning daylight and dollars? Imagine a world where you can predict these failures before they happen, saving time, reducing costs, and increasing productivity. This is no longer a futuristic dream. With a real-time maintenance alerts system, this scenario is within your grasp. Envision a seamless operation where every piece of equipment communicates its status, health, and potential maintenance needs well before a breakdown occurs. Welcome to the new era of maintenance management.

Read Now : Automotive Error Code Identification Guide

The Power of Predictive Monitoring

A real-time maintenance alerts system harnesses the power of predictive monitoring to keep your machinery in optimal condition. Imagine a scenario where sensors and data analytics work tirelessly to assess the condition of your equipment, predicting potential failures before they occur. This technology allows you to allocate resources effectively, schedule maintenance during non-peak hours, and reduce unexpected downtime. Your machinery will thank you by delivering consistent performance without the frustrating interruptions of unexpected failures. Experience the peace of mind that comes with knowing your operations are shielded from unforeseen breakdowns.

This real-time maintenance alerts system doesn’t just prevent failures; it transforms your entire approach to maintenance. By leveraging data insights and constant monitoring, your maintenance team can transition from a reactive mode to a proactive, even predictive, stance. Consider the competitive edge gained when your operations run smoother than your competitors. With real-time insights, your maintenance strategy becomes a strategic asset rather than a lingering overhead. Take the leap to smarter, data-driven operations and watch your bottom-line grow.

Benefits of Implementing a Real-time Alerts System

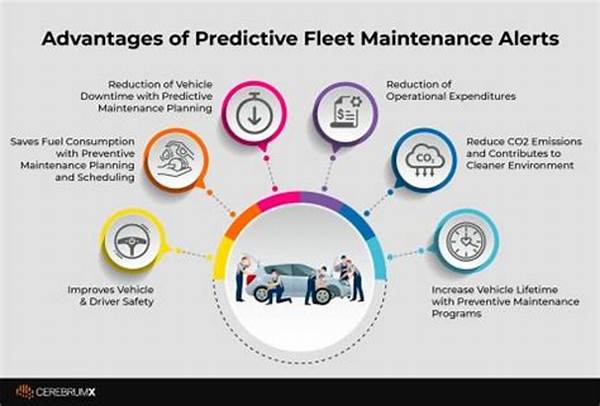

1. Minimized Downtime: A real-time maintenance alerts system ensures that downtime is reduced significantly by predicting issues before they become major problems.

2. Cost Efficiency: By knowing exactly when maintenance is required, the real-time maintenance alerts system saves on unnecessary repairs and optimizes resource allocation.

3. Extended Equipment Life: Continuous monitoring and timely alerts help in extending the life of your equipment, ensuring that you get the most out of your investments.

4. Improved Safety: The real-time maintenance alerts system also enhances workplace safety by addressing potential hazards before they escalate.

5. Enhanced Productivity: With machinery running at optimal levels, productivity is naturally enhanced as work progresses without interruptions.

Transforming Maintenance with Real-time Alerts

Adopting a real-time maintenance alerts system is not just about technology; it’s about transforming your organization’s culture towards innovation and efficiency. By integrating cutting-edge technology with daily operations, you challenge the status quo and set yourself apart as an industry leader. This proactive shift allows your team to focus on higher-value tasks rather than constant firefighting. As a result, staff morale increases, creating a culture of reliability and excellence.

Consider the strategic advantage gained by having real-time data at your fingertips. Decisions are no longer based on assumptions but are informed, data-driven, and timely. The real-time maintenance alerts system acts as a silent partner, constantly working to keep operations smooth and efficient. Companies that utilize this system are not just maintaining machinery; they’re securing their future in a competitive marketplace. Make the smart choice, and let your maintenance strategy give you a competitive edge.

Advantages and Explanations

1. Predictive Precision: The real-time maintenance alerts system provides precise data that enable preemptive action, eliminating guesswork and enhancing operational reliability.

2. Resource Optimization: This system significantly reduces waste by ensuring resources are used only when necessary, maximizing operational efficiency.

3. Data-Driven Decisions: With a real-time maintenance alerts system, decisions are backed by accurate data, leading to improved overall strategic planning.

4. Scalability: The system can easily scale with growing business needs, adapting to increased production without compromising on maintenance quality.

5. Environmental Impact: Proactively maintained systems tend to be more energy-efficient, reducing the environmental footprint of your operations.

Read Now : Prompt Vehicle Recovery Support

6. Regulatory Compliance: A real-time maintenance alerts system helps ensure compliance with industry regulations, avoiding penalties and enhancing credibility.

7. Customizable Alerts: These systems allow for tailored alert settings, ensuring that alerts are relevant and actionable for each specific machine or process.

8. User-friendly Interfaces: Intuitive dashboards and interfaces make it easy for personnel at all levels to interpret and act on maintenance alerts.

9. Reduced Human Error: Automation in alert systems minimizes the risk of human error, thereby maintaining high operational standards.

10. Cross-functional Benefits: Beyond maintenance, such systems can offer insights valuable to production, logistics, and overall business strategy, weaving maintenance insights into the fabric of business management.

Implementation Challenges and Solutions

The integration of a real-time maintenance alerts system into an existing operation may initially seem daunting, hindered by concerns about cost and disruption. However, the transformation it offers far outweighs these initial challenges. Leveraging IoT and AI technology, this system can seamlessly blend into your existing infrastructure. Once operational, the return on investment becomes evident through improved operational reliability and reduced costs.

Investing in training is also crucial to ensure that staff are adept at utilizing the system’s full potential. This step can be seen as an opportunity rather than a constraint. The skills acquired don’t just apply to the current system, but to an increasingly digital future in maintenance management. Organizations that hesitate to embrace these systems may find themselves outpaced by competitors who have optimized operations through real-time insights. Thus, the initial investment is more an investment in the future resilience and competitiveness of your operations.

Building a Continuous Improvement Cycle

Implementing a real-time maintenance alerts system is essentially about establishing a cycle of continuous improvement. Armed with accurate data and real-time feedback, organizations can pinpoint inefficiencies and areas needing improvement. This system encourages a culture of iterative advancement, where each alert becomes an opportunity to refine processes and enhance performance.

An ongoing cycle of data collection and responsive action transforms how operations are managed. Real-time insights help identify long-term trends that inform broader strategic decisions. Continuous improvement not only optimizes the immediate but molds the future of the organization. Over time, this constant evolution translates to elevated standards, reduced operational costs, and a profound ability to adapt to market changes rapidly.

The Future with Real-time Alerts

The future of maintenance is undeniably entwined with technologies like the real-time maintenance alerts system. As technology continues to advance, the capabilities of these systems will grow, becoming more sophisticated and powerful. Organizations that adapt early are poised to reap the significant benefits of improved equipment performance and cost efficiency. As the industry standards evolve, incorporating a real-time maintenance alerts system could be the difference between merely surviving and thriving in the marketplace.

In this ever-competitive landscape, the choice is clear: evolve your maintenance approach with a real-time maintenance alerts system or risk being left behind. These systems represent not just a technological upgrade but a fundamental shift towards smarter, more efficient business operations. Don’t wait until your competitors have taken the leap; position your organization at the forefront of innovation and performance today.

Incorporating a real-time maintenance alerts system is an investment in your organization’s longevity and success. As technologies evolve, so must our approaches to maintenance and operations. These systems offer a glimpse into a future where maintenance is no longer an operational headache but a streamlined component of strategic growth. Embrace the real-time maintenance alerts system and usher your organization into a new era of efficiency and excellence.