Integrated Engine Performance Diagnostics

In today’s fast-paced world, the success of your business relies heavily on the efficiency and reliability of your machinery. With constant technological advancements, keeping your engine in optimal condition is crucial. This is where integrated engine performance diagnostics come into play. Imagine having the ability to continuously monitor, assess, and optimize your engines’ performance, ensuring peak efficiency and minimizing downtime. By embracing this innovative solution, not only can you save time and money, but you can also stay one step ahead of potential issues, transforming the way you manage your operations.

Read Now : Cheap Vehicle Inspection Locations

Understanding Integrated Engine Performance Diagnostics

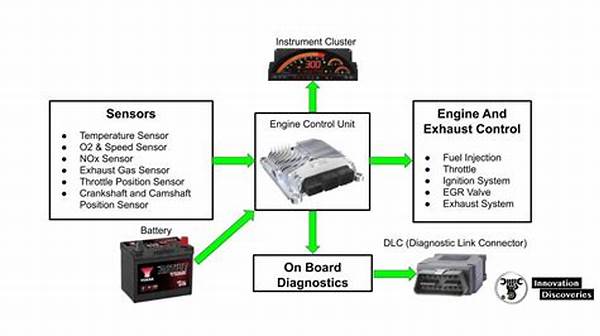

Integrated engine performance diagnostics is a game-changer for any industry reliant on engines. This technology provides a comprehensive analysis of your engine’s performance, allowing you to identify inefficiencies before they escalate into costly repairs. By systematically collecting and analyzing data, these diagnostics transform raw machine data into actionable insights. As a result, operators can make informed decisions, and maintenance can become predictive rather than reactive. Embracing integrated engine performance diagnostics helps you maintain seamless operations, minimize costs, and optimize the lifecycle of your machinery, securing your competitive edge in the market.

Utilizing integrated engine performance diagnostics offers countless benefits. It not only detects potential issues but also facilitates immediate action, reducing downtime significantly. With real-time analytics, you can optimize fuel consumption and reduce emissions, aligning with environmental sustainability goals. Additionally, integrated engine performance diagnostics extend the lifespan of your engines, ensuring they operate at their full potential. By leveraging this cutting-edge technology, you enhance both the efficacy and profitability of your business, making it an invaluable asset in today’s competitive landscape.

The Advantages of Real-Time Monitoring

1. Proactive Maintenance: Integrated engine performance diagnostics enable you to shift from reactive to proactive maintenance strategies, thus preventing costly breakdowns.2. Enhanced Efficiency: By optimizing engine performance, these diagnostics ensure maximum efficiency, consequently reducing operational costs.3. Data-Driven Decisions: The insights gained from integrated engine performance diagnostics empower you to make informed, strategic decisions based on concrete data.4. Environmental Impact: Integrating diagnostics helps in monitoring and controlling emissions, supporting your sustainability initiatives.5. Competitive Edge: Embracing state-of-the-art diagnostics positions your business as an industry leader, equipped with the latest technological advancements.

Maximizing ROI with Integrated Diagnostics

Investing in integrated engine performance diagnostics is not just an expenditure; it is a strategic investment. It assures a return on investment by minimizing downtime and optimizing resource utilization. Regular diagnostics pinpoint potential issues, allowing preemptive actions that prevent major breakdowns. This foresight not only curtails unplanned maintenance costs but also maximizes operational productivity.

With integrated engine performance diagnostics, businesses can align maintenance schedules with production demands, reducing interruptions and ensuring continuous operation. The benefits extend beyond immediate cost savings. Improved engine reliability enhances the customer experience and bolsters brand reputation. In today’s competitive market, where efficiency and reliability are prized, integrated diagnostics deliver sustainable value, driving your business toward transformative growth and success.

The Future of Engine Management

envisioning a future where integrated engine performance diagnostics are at the forefront of all engine management strategies is crucial. With advancements in artificial intelligence and machine learning, these diagnostics will become even more precise and indispensable. Predictive analytics will evolve, providing an unparalleled ability to foresee potential system failures and optimize performance proactively.

As industries strive for efficiency and innovation, integrating advanced diagnostics into engine management systems will no longer be optional but necessary. The seamless coordination of data-fueled insights and machine learning capabilities will redefine engine performance standards. By embracing this future, businesses not only secure their operations against unforeseen challenges but also position themselves for sustained success in an ever-evolving technological landscape.

Read Now : Auto Repair Quality Assessment Tools

Embracing Technological Innovations

By integrating sophisticated engine performance diagnostics, businesses can harness technology to drive unprecedented efficiency. Real-time data analysis allows for instant feedback and adjustments, optimizing engine outputs and reducing fuel consumption. Imagine cutting down energy costs and achieving top-tier performance. Such advancements pave the way for scalable growth and innovation, positioning your business as a leader in smart technology applications.

Sustainable Benefits for Business Growth

Incorporating integrated engine performance diagnostics into your operations translates into measurable economic and environmental benefits. Through detailed analysis and reporting, businesses can streamline operations, minimize waste, and meet sustainability targets. This approach not only supports environmental goals but also amplifies profitability, showcasing the dual benefits of technology-driven initiatives.

Summary of Integrated Engine Performance Diagnostics

Integrated engine performance diagnostics play a pivotal role in revolutionizing engine management by providing an in-depth understanding of engine systems. At its core, it empowers businesses with the ability to turn data into insights, enhancing operational efficiency and reducing unnecessary expenditures. In today’s competitive arena, time is money, and unplanned downtimes are costly. By adopting integrated engine performance diagnostics, businesses can anticipate issues before they escalate, translating to immediate cost savings.

Furthermore, by continuously optimizing engine performance, businesses can amplify their productivity and sustainability initiatives simultaneously. This dual benefit of enhanced performance and reduced environmental footprint positions integrated diagnostics as a critical tool for modern operations. As organizations continue to seek ways to innovate and thrive, integrated engine performance diagnostics offer a robust foundation for strategic growth, ensuring that they remain at the forefront of their industry.