“data-driven Maintenance Scheduling Techniques”

Imagine a world where your equipment never fails unexpectedly, where costly downtime is a relic of the past, and every decision is informed by precise data. This is not a distant dream but a current reality that can be achieved with data-driven maintenance scheduling techniques. The era of reactive maintenance is over, and the future belongs to those who embrace innovation and efficiency through data. Are you ready to transform your maintenance approach and optimize every operation to save time, money, and resources? Let’s delve into how data-driven maintenance scheduling techniques can revolutionize your business.

Read Now : Real-time Diagnostic And Prognostic Tools

Leveraging Analytics for Optimal Maintenance

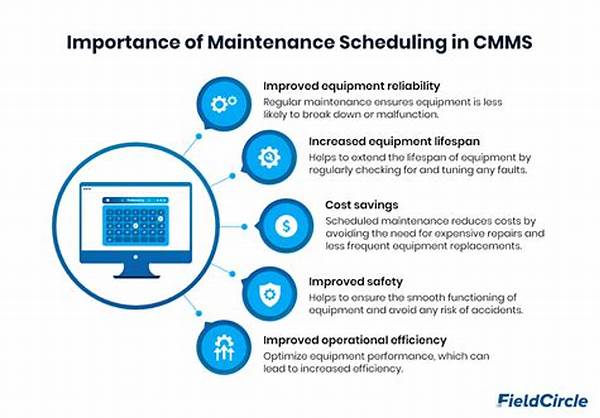

By integrating data-driven maintenance scheduling techniques, companies are not just predicting failures but preventing them before they happen. These techniques utilize vast amounts of data collected from machinery and equipment, transforming insights into actionable plans. Imagine the ability to analyze performance trends, predict components’ life expectancy, and schedule maintenance accordingly. This capability isn’t just theoretical; it’s a tangible advantage, enabling firms to lower operational costs and increase efficiency.

Adopting data-driven maintenance scheduling techniques means more than just upgrading technology; it’s about rethinking how you manage valuable assets. Maintenance teams that tap into the power of data can ensure higher uptime, fewer disruptions, and extended equipment lifespan. The shift to data-centric strategies can seem daunting, but the rewards are undeniable. Those who invest in these techniques can anticipate a return not only financially but also in enhanced operational control and foresight, driving their business forward in today’s competitive landscape.

Moreover, data-driven maintenance scheduling techniques empower teams by offering real-time insights into equipment health. The agility afforded by these techniques can transform maintenance from a reactive task into a strategic process. This evolution in approach can redefine maintenance planning, making it more predictive and less of a guessing game. Isn’t it time you started seeing maintenance as a strategic asset rather than a necessary expense? Unlock the potential of your operations and stay ahead in the game.

Transformative Impact on Maintenance Efficiency

1. Data-driven maintenance scheduling techniques ensure that maintenance is performed only when necessary, eliminating unnecessary downtime.

2. Utilizing these techniques reduces costly emergency repairs, safeguarding your budget and resources.

3. Implementing data-driven strategies leads to better resource allocation, preserving both time and manpower.

4. Data-driven maintenance scheduling techniques extend equipment lifespans, giving you more value for your investments.

5. Companies embracing these techniques see improved productivity and higher overall operational efficiency, yielding exceptional returns.

Realizing the Benefits of Data-Driven Strategies

In today’s fast-paced business environment, adopting innovative maintenance strategies is no longer optional. Data-driven maintenance scheduling techniques offer businesses unparalleled advantages by leveraging real-time data to predict and manage equipment health. Unlike conventional methods, these techniques empower companies to foresee potential issues and plan maintenance activities proactively, staying one step ahead of possible downtimes.

Data-driven maintenance scheduling techniques aren’t just about preventing failures; they’re about aligning maintenance efforts with strategic business goals. By harnessing the power of data, businesses can minimize disruptions, maximize productivity, and keep their systems running smoothly without incurring unnecessary costs. The question is not whether to adopt these techniques, but how quickly you can integrate them into your operations for a more resilient future.

Unleashing the Power of Predictive Maintenance

Understanding the full impact of data-driven maintenance scheduling techniques can be the game-changer your business needs. These methodologies not only enhance equipment reliability but also contribute significantly to strategic resource management. By turning data into predictive insights, businesses can tailor their operations to prevent failures and manage maintenance costs effectively.

These predictive maintenance techniques utilize a wealth of data, from operational metrics to machine learning algorithms, offering a detailed understanding of equipment conditions. Companies adopting such strategies find themselves better prepared to handle unexpected situations, translating data insights into pivotal business decisions. The competitive advantage is clear: efficiently managed operations that deliver unmatched service quality and customer satisfaction, contributing to a stronger market position.

1. Data-driven maintenance scheduling techniques revolutionize decision-making processes by providing actionable insights.

2. They significantly reduce the frequency and impact of unforeseen equipment failures.

3. With predictive capabilities, companies can allocate resources more judiciously, enhancing operational efficiency.

4. These techniques foster a culture of continuous improvement and innovation.

Read Now : Vehicle Maintenance Bundle Offers

5. Data-driven maintenance scheduling unlocks potential cost savings and performance optimization, offering a considerable competitive edge.

6. They enable precision in forecasting maintenance needs, avoiding unnecessary expenses.

7. By implementing these strategies, businesses ensure consistent production quality and reliability.

8. These techniques foster collaboration between IT and maintenance teams, optimizing technology use.

9. As predictive analysis becomes more intuitive, operational resilience strengthens.

10. Data-driven maintenance scheduling techniques emphasize the importance of insightful foresight in strategic planning.

A New Horizon in Maintenance Management

The introduction of data-driven maintenance scheduling techniques signals a new era in maintenance management, where data becomes the cornerstone of decision-making processes. This shift towards a more predictive maintenance model offers businesses the ability to manage resources with unprecedented precision and agility. Imagine a system where equipment repairs and upkeep are no longer dictated by rigid schedules but guided by real-time data insights revealing the most opportune moments for action.

The promising results of deploying data-driven maintenance scheduling techniques are evident. They offer the potential to diminish operational disruptions, improve resource allocation, and ultimately foster a leaner, more agile operation. Not only does this translate to direct cost savings, but it also leads to a more empowered and informed workforce. Maintenance teams, armed with accurate data, can execute their roles with higher efficiency and confidence, contributing to a more robust operational ecosystem.

The Strategic Edge of Predictive Techniques

In adopting data-driven maintenance scheduling techniques, businesses gain a critical strategic advantage. These techniques allow companies to align maintenance activities with broader organizational goals, ensuring resource optimization while maintaining high standards of operation. By predicting when maintenance activities should occur, businesses can better manage workloads, minimize disruptions, and maximize uptime.

Furthermore, data-driven maintenance scheduling techniques offer insights that extend beyond machinery and equipment. They facilitate a holistic view of the operational landscape, enabling companies to identify trends, foresee challenges, and capitalize on opportunities. The integration of these techniques into everyday practices ensures that organizations remain competitive, agile, and forward-thinking. As we navigate a future increasingly defined by digital transformation, data-driven approaches will remain at the forefront of operational excellence.

Embracing Transformation for Lasting Impact

The integration of data-driven maintenance scheduling techniques represents a significant shift for industries aiming to thrive in a competitive environment. By leveraging data as a strategic asset, businesses can shift from reactive to proactive maintenance approaches, significantly reducing operational hiccups and boosting overall productivity. The advantages are clear, but the journey requires a commitment to change and an investment in advanced technological solutions.

Data-driven maintenance scheduling techniques empower businesses to harness the full spectrum of data analytics, fostering an environment of continual improvement and foresight. By utilizing real-time data insights, companies can not only maintain the smooth operation of their machinery but also adapt quickly to changing demands and challenges. This agility ensures businesses can not only survive but thrive, remaining robust and resilient in an ever-evolving marketplace.

For leaders and decision-makers, embracing these innovative strategies is no longer an option but a necessity. The focus is on maximizing value and minimizing waste, creating an efficient and effective operation that meets the demands of modern business. By adopting data-driven maintenance scheduling techniques, businesses can lay the groundwork for a sustainable, competitive advantage that drives long-term growth and success. In this journey, data is not just a tool but a powerful enabler of transformational change.