High-quality Tools For Fleet Repairs

In an industry where time equals money, the efficiency and reliability of your vehicle fleet can make or break your business. Investing in high-quality tools for fleet repairs is not just a luxury but a necessity. Imagine a world where you can swiftly address vehicle issues, reducing downtime and enhancing fleet performance. This vision is within reach when you equip your repair operations with the right tools that are tailored for the task. Let us delve into how these high-quality tools can transform your fleet maintenance operations and contribute to your business’s success.

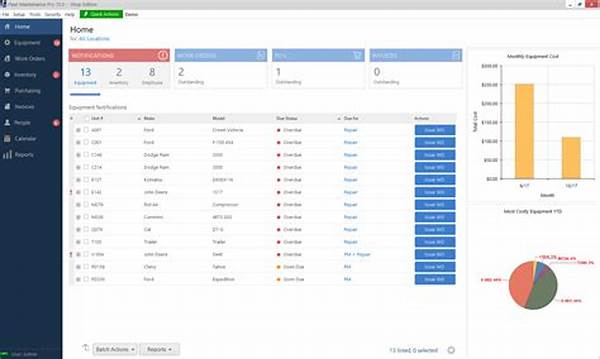

Read Now : Auto Maintenance Management Platform

The Importance of High-Quality Tools for Fleet Repairs

Choosing high-quality tools for fleet repairs is essential for ensuring the safety and longevity of your vehicles. When your fleet is the backbone of your business, using inferior tools can lead to inadequate repairs, resulting in frequent breakdowns and safety hazards. High-quality tools guarantee precise diagnostics and efficient repairs, extending the life of your fleet and reducing operating costs. By investing in these tools, you’re not only safeguarding your vehicles but also ensuring timely service delivery, which can significantly enhance customer satisfaction. Trust high-quality tools for fleet repairs to keep your business running smoothly and competitively.

Five Reasons to Invest in High-Quality Tools for Fleet Repairs

1. Enhanced Efficiency: High-quality tools for fleet repairs speed up the process, enabling technicians to complete tasks quickly and efficiently, thus minimizing vehicle downtime.

2. Improved Safety: With robust and reliable tools, the risk of accidents during repairs is significantly reduced, ensuring a safer working environment.

3. Cost-effective: While the initial investment might be higher, high-quality tools reduce the frequency of repairs and part replacements, saving money in the long run.

4. Precision and Reliability: High-quality tools provide accurate diagnostics and repairs, ensuring vehicles are fixed right the first time.

5. Longevity of Fleet: Regular maintenance with top-grade tools keeps vehicles in peak condition, extending their operational lifespan and boosting overall productivity.

Why Quality Matters in Fleet Repair Tools

Every professional in the fleet maintenance industry understands the critical role that high-quality tools for fleet repairs play in day-to-day operations. The significance of these tools goes beyond immediate repairs; they are fundamental in identifying potential issues before they evolve into costly problems. Quality tools provide precise and accurate diagnostic capabilities, allowing technicians to address even the most intricate repair challenges efficiently. Investing in top-tier tools is a small price to pay to prevent minor issues from escalating, thus saving your business from unexpected expenses and unwanted downtime.

Moreover, high-quality tools for fleet repairs inspire confidence among technicians. Knowing they have reliable and effective equipment at their disposal, they can focus on executing repairs with unmatched precision and care. This improved workflow not only enhances the repair quality but also boosts the morale and job satisfaction of your maintenance team. Equipping your workforce with the best tools demonstrates a commitment to excellence, fostering a culture that values quality, precision, and continuous improvement in fleet management.

Benefits of Equipping Your Fleet with High-Quality Tools

1. Durability: High-quality tools for fleet repairs are built to last, able to withstand the rigors of daily use without compromising performance.

2. Versatility: These tools are designed to handle a wide variety of repairs, making them invaluable assets for any fleet maintenance operation.

3. Efficiency: They streamline workflows, helping technicians complete jobs faster without sacrificing quality.

4. Accuracy: Precision in repair work leads to fewer mistakes and long-lasting fixes, which translates to happier clients.

5. Reputation: Using the best tools and delivering timely repairs enhances your business’s reputation for reliability and professionalism.

6. Competitive Edge: Businesses equipped with high-quality tools for fleet repairs can offer superior services, gaining an advantage over competitors.

Read Now : Accredited Vehicle Repair Facilities

7. Employee Satisfaction: Technicians feel valued and efficient when they have access to the best equipment to perform their tasks.

8. Reduced Liability: Quality tools minimize the risk of errors and accidents, reducing potential liabilities for your business.

9. Sustainability: By reducing the need for frequent tool replacements, you minimize waste and operate more sustainably.

10. Innovation: Regular updates and advancements in tool technology keep your repair processes at the industry forefront.

Ensuring Optimal Performance with High-Quality Tools for Fleet Repairs

In the demanding world of fleet management, the role of high-quality tools for fleet repairs cannot be underestimated. Not only do they enhance operational efficiency, but they also ensure optimal vehicle performance. High-quality tools are integral to performing thorough inspections and timely repairs, which are essential for avoiding the cascading effects of vehicle failures. This is crucial for maintaining service schedules and upholding your company’s reputation for reliability.

Quality tools also empower your team, boosting morale and efficiency by minimizing frustrations associated with inferior equipment. With the assurance that they’re using premium-grade tools, technicians can conduct repairs with confidence and precision. This approach not only secures the safety and reliability of each vehicle but also reflects positively on your business as a whole. When high-quality tools are standard practice, excellence in fleet maintenance becomes an expectation rather than a hope, setting your business apart in a competitive industry.

Elevating your toolkit with these tools is a straightforward yet powerful strategy for any business that relies on a fleet. It ensures that your fleet is always ready to meet operational demands, no matter how challenging, providing peace of mind and reliability. Furthermore, with high-quality tools for fleet repairs, you mitigate the risk of extensive breakdowns, contributing to cost savings and enhancing your fleet’s value.

The Impact of High-Quality Tools on Fleet Management

Fleet managers recognize that maintaining an efficient operation is largely contingent on the tools available for repairs. High-quality tools for fleet repairs are pivotal to maintaining the high standard expected by your clients and business partners. They provide an extra level of assurance that repairs will be done correctly and sustainably. Such tools also provide a competitive advantage, demonstrating a commitment to excellence and reliability in every service you deliver.

Investing in high-quality tools emphasizes a foresight-driven approach towards fleet management, where the focus shifts from merely repairing breakdowns to preventing them. This proactive stance enhances service reliability and can potentially lead to a reduction in overall maintenance costs. The long-term benefits of reliable tools include not only financial savings but also brand loyalty from satisfied customers who value dependable service. When you prioritize high-quality tools, you position your company as a leader in efficiency and reliability, transforming your fleet into an asset characterized by trust and durability.

Summary of High-Quality Tools for Fleet Repairs

In conclusion, the use of high-quality tools for fleet repairs is an indispensable aspect of successful fleet management. These tools minimize repair times, maximize efficiency, and underscore your commitment to quality and reliability. Investing in superior tools not only enhances your fleet’s operational efficiency but also fortifies the safety and dependability of your vehicles. With precision and reliability at the forefront, your fleet remains exemplary, reflecting the high standards your business strives to uphold.

Furthermore, the decision to procure high-quality tools for fleet repairs is not merely an operational choice but a strategic investment. It ensures that your fleet is capable of responding to demands swiftly and effectively, thus keeping your operations uninterrupted and client satisfaction high. By committing to quality tools, you bolster your business’s reputation, improve employee morale, and ultimately, ensure the longevity and effectiveness of your fleet. Choosing high-quality tools means choosing reliability, excellence, and a prosperous future for your fleet-dependent business.