“efficient Equipment Maintenance Planning”

In today’s fast-paced industrial landscape, efficient equipment maintenance planning is not just a preferred practice; it’s an absolute necessity. Companies that fail to implement strategic maintenance suffer from unexpected downtimes, skyrocketing costs, and reduced productivity. Conversely, organizations that prioritize efficient equipment maintenance planning not only safeguard their operations but also gain a competitive edge. Imagine a world where all your machinery runs smoothly without unexpected breaks, saving time and resources. This is the world efficient equipment maintenance planning offers, a reality within reach for those willing to adapt and invest in strategic foresight.

Read Now : Transparent Auto Repair Pricing

The Importance of Preventive Maintenance Strategies

Efficient equipment maintenance planning is a fulcrum upon which successful business operations balance. It’s not just about responding to machine failures—it’s about proactively preventing them. Implementing preventive maintenance can drastically reduce unexpected downtimes, which often cost businesses thousands of dollars per hour. Moreover, a strategic maintenance plan extends machinery lifespan, ensuring investments yield maximum returns over time. Companies that embrace efficient equipment maintenance planning typically witness a significant boost in efficiency and productivity. The foresighted nature of such plans also enables businesses to allocate resources more effectively, contributing to sustained growth and success. The key to unlocking these benefits lies in embracing a preventive approach, integrating it seamlessly into daily operations.

The Economic Benefits of Routine Maintenance

1. Cost Reduction: Efficient equipment maintenance planning reduces the likelihood of costly emergency repairs. Preventive measures are far less expensive than dealing with unexpected breakdowns, offering immediate and long-term financial savings.

2. Increased Equipment Lifespan: Regular maintenance ensures that machinery operates within optimal conditions, thereby extending its life. This means infrequent capital expenditure on new equipment, freeing resources for other business needs.

3. Operational Efficiency: Efficient equipment maintenance planning leads to smoother operations. Machines in top condition perform better, enhancing productivity and ensuring deadlines are consistently met.

4. Energy Efficiency: Well-maintained equipment often uses energy more efficiently, reducing utility costs. This not only supports cost-saving but also aligns with corporate sustainability goals.

5. Employee Productivity: Reduced equipment failure means employees can work without disruptions, improving morale and efficiency. Maintenance planning ensures that resources are concentrated on productivity rather than crisis management.

Read Now : Rapid Vehicle Maintenance Support

Key Steps in Developing an Effective Maintenance Plan

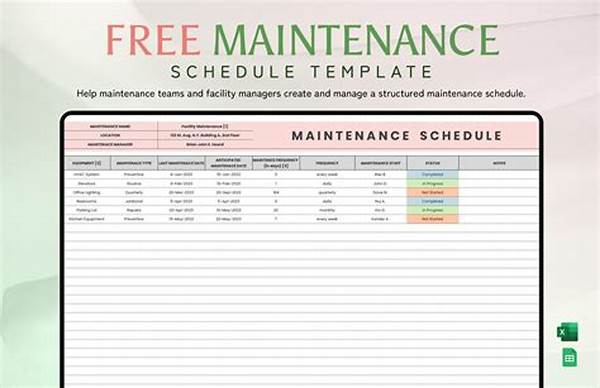

Efficient equipment maintenance planning begins with understanding your machinery and its specific needs. One of the first steps is conducting a thorough audit of all equipment to identify areas prone to failure. This facilitates the creation of a tailored maintenance schedule, ensuring critical components receive due attention before issues arise. Investing in training for maintenance personnel enhances the efficacy of the planning process, as skilled workers can often diagnose and resolve issues before they escalate. Additionally, leveraging technology such as predictive maintenance software can elevate strategies by providing real-time data, helping predict failures before they occur. Each step is an investment in the longevity and productivity of your business operations, making efficient equipment maintenance planning an indispensable strategy for any forward-thinking organization.

Technological Integration in Maintenance Scheduling

Technology plays a pivotal role in enhancing efficient equipment maintenance planning. With the advent of IoT and AI-powered tools, companies can now monitor equipment health in real-time. For instance, sensors attached to critical machinery parts can send data directly to central systems, alerting maintenance teams to potential issues immediately. This proactive approach minimizes downtime and ensures resources are always optimally allocated. What’s more, predictive analytics can anticipate failures based on historical data, allowing teams to schedule maintenance before problems arise. Efficient equipment maintenance planning, enhanced by technology, leads to significant increases in both productivity and cost savings, proving that digital transformation truly pays off when integrated wisely into maintenance strategies.

The Role of Training and Personnel in Maintenance Efficiency

In any strategy aimed at efficient equipment maintenance planning, human resources play a critical role. Well-trained personnel can significantly enhance the efficiency of maintenance efforts. Regular training and skills enhancement programs equip technicians with the latest knowledge and techniques to maintain machinery at peak performance. Additionally, fostering a culture of preventive maintenance within the workforce encourages proactive engagement, reducing the occurrence of unexpected equipment failures. Personnel who understand the intricacies of machinery and the importance of maintenance are more likely to catch potential problems early, thus protecting the organization from costly interruptions. Efficient equipment maintenance planning is as much about people as it is about machines, underscoring the importance of developing a skilled maintenance workforce.

Summary of Efficient Maintenance Planning’s Impact

Efficient equipment maintenance planning is a transformative strategy for any business with significant machinery investments. By emphasizing preventive measures and leveraging technology, companies can drastically reduce unexpected downtimes. This not only leads to direct financial benefits by curbing repair costs but also extends the lifespan of expensive equipment. Importantly, such planning supports operational efficiency, as well-maintained equipment performs optimally, ensuring productivity goals are consistently met. It also positively impacts employee morale by minimizing disruptions and creating a more predictable work environment. Ultimately, efficient equipment maintenance planning functions as a cornerstone of a resilient and competitive business, aligning operational strategies with broader corporate objectives and ensuring lasting success.