Load-bearing Fatigue Assessment

In today’s dynamic world, where infrastructure demands are escalating rapidly, the significance of load-bearing fatigue assessment cannot be overstated. This pivotal process not only ensures the safety and longevity of structures but also optimizes their performance and cost-effectiveness. By proactively evaluating the fatigue life of critical components, industries can avoid catastrophic failures, reduce maintenance costs, and extend the service life of their assets. It becomes increasingly clear that integrating load-bearing fatigue assessment into your engineering practices is not merely an option but a necessity. It is time to prioritize safety and efficiency in your projects.

Read Now : Necessary Instruments For Auto Tune-ups

The Importance of Load-Bearing Fatigue Assessment

Load-bearing fatigue assessment is paramount for engineers and developers aiming to ensure their structures withstand the test of time and usage. This method provides invaluable insights into how materials will perform under repeated stress over time, helping identify potential failures before they occur. By implementing load-bearing fatigue assessment, organizations can safeguard human lives and protect huge financial investments in infrastructure. Considering the potential costs of neglect, which may include structural failures and legal liabilities, investing in comprehensive load-bearing fatigue assessment emerges as a not only wise but essential decision for lasting safety and efficiency.

Key Benefits of Conducting Load-Bearing Fatigue Assessment

1. Safety Assurance

Load-bearing fatigue assessment provides critical data, ensuring structures withstand operational demands without unexpected failures.

2. Cost Reduction

Identifying issues early minimizes costly repairs, making load-bearing fatigue assessment a financially sound investment.

3. Longevity of Structures

Proper assessment extends the lifespan of components, ensuring sustainable infrastructure with prolonged service life.

4. Optimal Performance

Load-bearing fatigue assessment guarantees that structures operate efficiently, bridging the gap between safety and functionality.

5. Compliance and Confidence

By adhering to industry standards through load-bearing fatigue assessment, stakeholders gain trust and confidence in structural integrity.

Load-Bearing Fatigue Assessment and its Extensive Applications

Understanding the extensive applications of load-bearing fatigue assessment can revolutionize how industries approach structural safety. Whether in aerospace, construction, or automotive sectors, precise evaluation methods determine the durability of components, thus preventing unanticipated downtimes. This holistic approach allows engineers to tailor maintenance schedules and design enhancements that bolster the overall efficiency and safety of structures.

Read Now : Affordable Car Radiator Repair Services

In automotive industries, load-bearing fatigue assessment plays an instrumental role in enhancing vehicle durability by identifying stress points and reinforcing them against potential failures. Similarly, in aerospace, the meticulous testing of aircraft components through fatigue assessment guarantees passenger safety and aircraft performance. The benefits of adopting rigorous load-bearing fatigue assessment are limitless, paving the way for structures that are resilient, efficient, and sustainable.

Load-Bearing Fatigue Assessment: A Strategic Imperative

The strategic imperative of load-bearing fatigue assessment cannot be overstated. The process empowers organizations to anticipate issues and create robust strategies for maintenance, thereby avoiding the high costs of reactive repairs. In environments where failure is not an option, such as nuclear plants or bridges, fatigue assessment ensures operational continuity and safety.

Incorporating load-bearing fatigue assessment in your strategy allows for the proactive management of assets, leading to substantial savings in both time and money. This foresight ensures that your infrastructure remains resilient and reliable, even under the most strenuous conditions. Ultimately, load-bearing fatigue assessment is not merely a practice but a strategic paradigm critical for excellence in engineering.

Techniques in Load-Bearing Fatigue Assessment

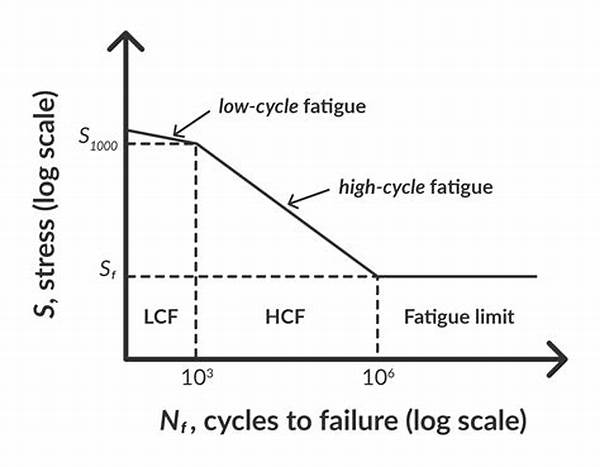

The techniques employed in load-bearing fatigue assessment are as diverse as they are critical. From simulation models to physical testing, each method provides unique insights that enhance the reliability of assessments. By employing advanced techniques such as Finite Element Analysis (FEA) and strain-life testing, engineers can predict and simulate real-life stressors accurately.

These methods are vital in understanding the fatigue characteristics of materials and structures. Load-bearing fatigue assessment techniques intertwine science, engineering, and technology to create robust systems capable of withstanding operational demands. By leveraging these techniques, industries can pursue innovative designs that push the boundaries of what’s possible while maintaining essential safety standards.

Practical Applications of Load-Bearing Fatigue Assessment

In practice, load-bearing fatigue assessment finds relevance across diverse sectors with transformative impact. For industrial firms, assessing fatigue helps optimize equipment maintenance schedules, reducing unforeseen downtimes and boosting productivity. For civil engineers, it translates to safer, longer-lasting bridges and buildings, shielding communities and economies from potential disasters.

Moreover, in the realm of transportation, load-bearing fatigue assessment ensures the strength and durability of roads, bridges, and vehicles, fostering public confidence in safety. By embedding these assessment practices into everyday operations, companies anchor themselves on a proactive approach to safety, ultimately achieving more reliable and efficient systems that face the challenges of tomorrow head-on.

Summary of Load-Bearing Fatigue Assessment

In conclusion, the adoption of load-bearing fatigue assessment is integral to the sustainable development of modern infrastructure. Through this process, industries across various sectors can identify weaknesses before they manifest as critical failures, thereby maximizing safety and efficiency. The foresight offered by load-bearing fatigue assessment saves industries significant costs while enhancing the longevity and performance of structures.

Conclusively, incorporating load-bearing fatigue assessment into your operational and design processes positions your organization at the forefront of safety and innovation. It not only mitigates risk but also offers strategic advantages by fostering a culture of proactive maintenance and compliance. This commitment to quality and integrity ensures that your infrastructures are equipped to meet both today’s demands and tomorrow’s challenges with resilience and reliability.