Integrated Automotive Lifecycle Strategy

Unlocking the full potential of your automotive products has never been more critical in today’s fast-evolving market. An integrated automotive lifecycle strategy is not just a luxury—it’s a necessity. This holistic approach ensures that every part of a vehicle’s lifecycle, from conception and design to production and end-of-life management, is streamlined for optimal efficiency and sustainability. By embracing this strategy, you’re not just keeping up with the industry; you’re setting the pace. Imagine transforming your automotive processes to be more agile, eco-friendly, and cost-effective. It’s time to reimagine the automotive lifecycle with a comprehensive, integrated approach. Let’s delve deeper into its immense benefits and seize the opportunity to lead the charge in automotive innovation.

Read Now : Experienced Brake Maintenance And Repair Team

Understanding the Need for an Integrated Automotive Lifecycle Strategy

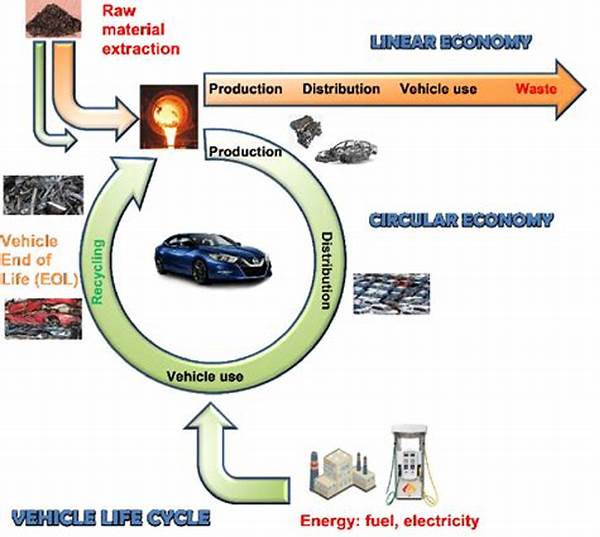

The global automotive industry is experiencing unprecedented shifts driven by technological advancements, changing consumer preferences, and stringent regulations. An integrated automotive lifecycle strategy offers a blueprint for navigating these changes effectively. By synchronizing each phase of the lifecycle—from research and development to post-consumer recycling—companies can enhance efficiency, reduce costs, and minimize environmental impact. This strategy is key to unlocking substantial competitive advantages. Imagine a world where your design and manufacturing processes are seamlessly aligned, your supply chain is optimized, and your vehicles meet increasing sustainability demands. Such synchronization leads to faster time to market, better product quality, and increased brand loyalty. Car manufacturers and suppliers implementing this strategy find themselves not just surviving, but thriving amid industry fluctuations. They are better equipped to innovate and adapt, positioning themselves as leaders in a rapidly changing landscape. Thus, for automotive players aiming to future-proof their operations, investing in an integrated automotive lifecycle strategy is not just advisable—it’s essential.

Key Benefits of Implementing an Integrated Automotive Lifecycle Strategy

1. Enhanced Efficiency: An integrated automotive lifecycle strategy reassesses each process in the vehicle’s lifecycle for redundancy reduction and better resource allocation, driving enhanced efficiency throughout the company.

2. Cost Reduction: By aligning all lifecycle stages, companies can significantly lower costs associated with production errors, waste, and inefficiencies.

3. Sustainability: This strategy integrates eco-friendly practices, ensuring compliance with regulations and addressing consumers’ growing demand for sustainable products.

4. Innovation Stimulation: Continuous feedback and interconnected workflows boost innovation, helping companies to maintain a competitive edge.

5. Market Responsiveness: By creating seamless operations, organizations can respond swiftly to market changes and consumer needs.

Shaping the Future with an Integrated Automotive Lifecycle Strategy

The race towards a sustainable and efficient future is on, and only those with foresight will emerge victorious. Embracing an integrated automotive lifecycle strategy is the industry’s secret weapon. It is an approach that leverages interconnected systems to drive sustainability and spur rapid innovation. Every aspect, including design, development, manufacturing, and recycling, is synchronized to ensure seamless operations. This complete lifecycle management leads to reduced time to market and optimized resource use, key factors in gaining market leadership. Companies adopting this strategy are better positioned to tackle challenges and capture emerging opportunities, ensuring they remain competitive in an ever-evolving marketplace. They are not only building vehicles but also shaping the future of transportation, one with eco-friendly, high-performing cars that consumers adore. By undertaking this journey of integration, automotive companies are not just preserving their legacy—they are defining it.

Detailed Aspects of an Integrated Automotive Lifecycle Strategy

1. Streamlined Processes: An integrated automotive lifecycle strategy ensures that each phase, from ideation to disposal, is interconnected, reducing inefficiencies.

2. Cost Efficiency: By minimizing waste and errors, this strategy results in substantial cost savings, benefiting both the company and consumers.

3. Sustainability: Incorporating eco-friendly practices throughout the lifecycle not only meets regulatory standards but also garners brand loyalty among eco-conscious consumers.

4. Agility: With seamless communication between departments, companies can pivot quickly in response to market shifts, staying ahead of competitors.

Read Now : Understanding Diagnostic Trouble Codes

5. Innovation: Integrating feedback and continuous improvement fuels innovation and pushes the boundaries of automotive technology.

6. Quality Enhancement: Ensures consistent product quality due to streamlined quality checks at each lifecycle phase.

7. Brand Reputation: Demonstrating a commitment to sustainability and efficiency boosts brand image and consumer trust.

8. Market Leadership: Early adopters of this strategy set industry standards and influence trends.

9. Customer Satisfaction: Streamlined processes result in quicker delivery times and improved product performance, enhancing customer satisfaction.

10. Regulatory Compliance: Proactively addresses regulations, avoiding penalties and fostering goodwill with governing bodies.

Practical Implementation of an Integrated Automotive Lifecycle Strategy

A seamless integration of processes is paramount for automotive companies striving for excellence. An integrated automotive lifecycle strategy provides the comprehensive framework needed to achieve just that. By embedding sustainability and efficiency into the core of company operations, this strategy enables automotive firms to transform challenges into opportunities. Through meticulous planning and coordination, every phase in the automotive lifecycle is aligned, ensuring resources are optimized, and waste is minimized. This holistic integration not only bridges existing gaps but also paves the way for future innovations. Companies implementing this approach can revolutionize their business models, guiding the industry towards a sustainable, efficient future. Suppose your company is looking to elevate its operational excellence—then this strategy is your ticket to success. By fostering an environment that champions collaboration and continuous improvement, you will elevate your organization from a mere participant to a trailblazer in the automotive realm.

Summary of the Integrated Automotive Lifecycle Strategy’s Impact

The strategic integration of automotive products’ lifecycle is pivotal in today’s fast-paced industry. An integrated automotive lifecycle strategy transcends traditional practices by harmonizing every stage from creation to recycling. This approach not only addresses eco-conscious consumers’ demands but also enhances operational efficiency. By systematizing processes and aligning resources to reduce waste, companies experience unprecedented growth. The strategy empowers automotive leaders to anticipate changes and respond adeptly, turning potential disruptions into competitive advantages. The beautiful synergy between sustainability, innovation, and agility fosters an ecosystem where automotive firms flourish. As they spearhead this transformative journey, they underscore the importance of future-ready strategies. They encapsulate the essence of industry evolution, creating vehicles that align with modern consumers’ values and expectations. This strategy doesn’t merely follow trends; it defines them, setting a new benchmark for the industry’s future trajectory. For any automotive entity determined to maintain relevance and prosperity in an ever-evolving landscape, embracing this integrated approach is imperative.